hey everybody!

its been about a month and a half since i got the 7.5hp conversion flying. the wind gods have not been very nice and have been holding back on the wind. i did manage to be home a few times when we got some fair wind though. best i have seen so far is approx. 2kw into my element bank. my heating bank is an 18kw @208 volt 3 phase unit. comes out of a roof top heater as back up with natural gas being the main heat source.

the element bank consists of 6 nichrome wire elements. the original connection had the unit split into two parts. each part was connected delta, and the two parts were then paralelled. what i am doing my testing with is just 1/2 of the unit connected star. the ohm reading when connected star is 28 ohm between any two phases. my gen, connected at 1 star connection, measures approx 2 ohm between any two phases. the gen is a 12 pole unit, designed to give 240 volt at 600 rpm unloaded voltage.

i have been testing to date using voltage relays to pull the first half of the heating bank on line at approx 85 volt, and the second half of the bank comes in at approx 140 volt line voltage. i have been using 208 volt 3 pole relays to carry the load. i have rectified the control voltage to DC which does a good job of keeping the contactors from chattering.

problem so far has been that most of the time, the genny is running under 85 volt, and basically i am loosing everything under that voltage.

lately i have seen some discussion on the board about using capacitors to work with the gen and elements for a heating system. as i understand it, the idea with the caps is to change the power curve from squared to cubed.

i have done this today with the caps connected in series with the 3 phases. i basically removed the plate on the heating element bank that made the star connection and put the caps in series with the 3 phases. when you take an ohm reading between any 2 of the 3 input studs on the element bank with the caps connected, it basically shows an open circuit. the gen starts up in the smallest breeze with the element and caps bank direct connected to the gen.

first, i will show you a few pics of my messy panel, the capacitors, and the element bank. then the results.

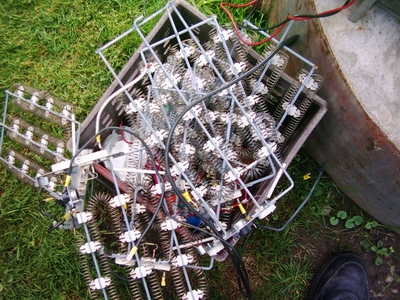

the 18 kw 208 volt 3 phase heating bank

here you can see some of the capacitors. some of them are hidden. at present, i have 200 MFD (2x60mfd plus 1 80 MFD in paralell) per phase. they are 370 and 440 volt caps (motor run caps)

here is one of the 60MFD x440 volt caps

here is a bunch of other elements i have been testing with in different configurations. each one is a 3.4 kw 230VAC element.

i have taken pictures of the meters showing the output. the meter on the left is the AC voltage, the meter on the right is the amperage. the formula i use to determin wattage output is volts X amperage X 1.73 the weather man says winds today are 10kph (6.2 mph) it might have been a little more with the gusts. the results are quite interesting.

29.7 volt x .2 amp = 10.27 watt

47.6 volt x .76 amp = 62.58 watt

55.8 volt x 1.06 amp = 102.32 watt

66.3 volt x 1.52 amp = 174.34 watt

77.5 volt x 1.98 amp = 265.46 watt

the results i find are quite interesting. seems to be a huge jump in watts with little gain in voltage. the last 2 tests show approx a 90 watt jump with 11 volt gain.

if someone with a little more insight as to what is going on here, please share your wisdom so that i may understand this better myself. i anxiously look forward to some good strong wind to see what happens with total output.

thats it for now folks, and when i have some better wind i shall share the results with you.

zubbly