Hi -

"In reading the descriptions of alternator construction on OtherPower.com I've noticed that 3-phase seems to be preferred in larger devices."

I'd say it's preferable in all size generators unless single phase AC is our final product. If we're rectifying the output to DC, then 3 phase is the way to go. Size is not an issue.

"I'm having trouble visualizing what the output curve looks like from a 3-phase alternator. I'm guessing it produces lower peak voltage but at a higher AC frequency. "

No... the frequency and voltage can be whatever we wish in either case. 3 phase is delivered on 3 wires and at any time youll have single phase AC between any two wire. Each set of two wires carries single phase AC. So we sort of have 3 single phase outputs, except that they share conductors. So we have current flowing through all the conductors all the time. Single phase has at least a moment where no current is flowing in the line, during that time our whole machine, and the line between the machine and the batteries is doing nothing. With 3 phase, everything is working all the time so were making more efficient use of conductors (and magnets).

When there's 0 current flowing in a single phase machine, there's also 0 torque required to turn the alternator. At the peak of the sine wave (maximum current flowing) it takes maximum torque to turn the alternator. So it 'cogs' while producing power. You can feel that in your single phase machine if you short it out - itll feel stiff to turn, but very lumpy. This makes noise and tends to rattle things apart. 3 phase is very smooth because we're making power all the time.

" I'm trying to decide how to wire my second alternator. What would make you chose one method over the other?"

I would make it 3 phase!

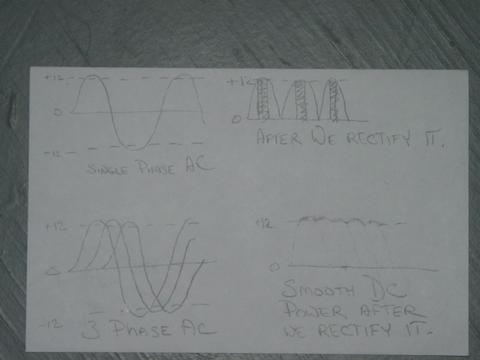

Sorry for the rough picture there..

But you can see in the picture at the top left what single phase AC looks like. On the right top, is what you get if you rectify that to DC. I put a line at the top there and called it 12V (imagine were charging a 12 V battery). The DC is very lumpy, and current only flows when the voltage is over 12V. With single phase, any time the voltage is below that line - our alternator and all the wires are doing nothing. So at, or near cutin on a wind turbine - much of the time no current is flowing at all in a single phase machine. Even at full output there would be a good deal of time where no current is flowing.

The bottom left picture shows what 3 phase looks like and you can see that once we rectify it to DC we have very nice smooth (slightly lumpy) DC current.

Here is a good link that helps explain this too on Ed's page:

http://www.windstuffnow.com/main/3_phase_basics.htm