When I first saw the volvo windmill, I got very excited. 2 years or so later, I build my own a bit smaller and with the original 1 disk setup. The mags are really small so I really think 200 watts will be fun to have.

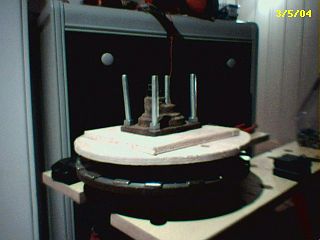

The disk and bearing are from many models of the same platform of GM cars with rear disk brakes (90's Buick Regal, Pontiac Grand-Prix etc). They have small disks but the standard bold patern makes it good for upgrades within GM bigger cars front disks. The bearing is sealed all around and should be pretty tough for a small mill.

The magnets are small 3/4" x 3/4" x 1/6" so I might stack 2 of them. I would like to make 3 phases to reduce cogging and make it effective so I'll use a total of 16 magnet stacks for 12 coils. I will use polyester resin to cast the stator and the rotor with some fiberglass inserts for the later.

Here is a test with a 50 turns coil of #20 wire turning around 120-150 RPM (poor rechareable drill takes it hard). More elaborated testing to come.

There is a diode and capacitor which take care of the ripples but I suspect it boost the output a bit. Will use a LED to bleed it a bit next time.

Here is the back with studs coming out. These will go in the aluminum body i have prepared in foam. I will just beef it up a bit for security sake before I cast it.

As you might have seen, the gap is significant. I want to keep space for the minimalist laminates. I am really thinking into making the whole backing assembly in aluminum as the wood parts are lousy.

Here you can see how I spin the thing. NOT recommended to let go the throttle at full speed with a high geared cordless drill. The reading is open AC volts with same coil as above in earlier tests. Must be RMS volts as it is much lower in truth.

And here are early coil pics. The one on the left is the good one. The one on the right was ways too large and would only produce half the power of the smaller one.

I'll keep adding up more pics as it goes. All comments are welcome.