At the end of part 2 I had wound all the 6 coil sets and got the first one installed in the stator. Next day I forged ahead and fitted the remaining 5 coil sets. I did get quite a lot quicker with each one but it was still a very fiddly process. The hole in the stator is only about 2 3/4 inches diameter so there's not much room to get fingers inside. Also because I had used 6 thin wires in parallel to wind the coils, there were 450 wires to get in each slot! The last coil set to go in was by far the worst as all the other coils get in the way.

If you attempt a conversion like this make sure you fit the coils in this order otherwise you will have problems where they have to cross over each other.

At last! All coils are in!

A shot of the new slot insulation This was cut from OHP film. The ends are folded back on themselves and spring out when the insulation is fitted, locking the insulation firmly in place.

The stator was then fitted back into the motor casing, the coil ends fitted with sleeving and all loose wires tied in place. I decided to bring all the coil ends outside so I could swap the connections around easily. A waterproof connector box will be fitted to the outside of the case.

The rotor and end plates were refitted and then all the coil ends were stripped of enamel and all six wires in each end twisted and soldered together.

The rotor spins reasonably easily with only a trace of cogging (thanks to the skewed magnets). I have used the old bearings for the time being which are a little tired but new ones will be fitted when the genny is stripped for painting etc.

Time for some testing!

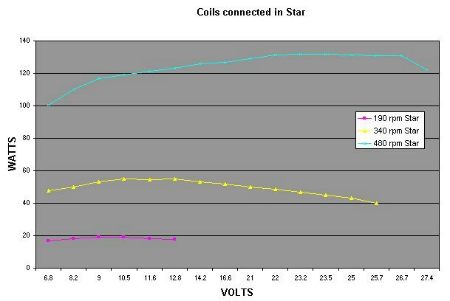

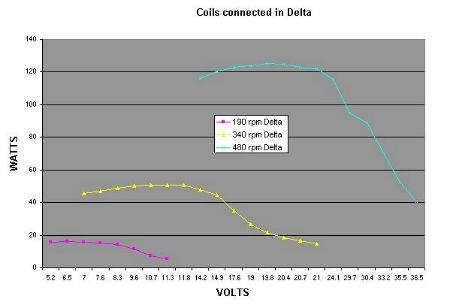

The motor was mounted in the lathe and run at three speeds with the coils connected firstly in 'Star' and then repeated with them connected in 'Delta'. I measured the voltage and current produced at each speed with a load consisting of a large variable resistor (a length of heater element with a crocodile clip to change the resistance!). The voltage and current readings were taken with different values of the resistor to find the maximum power output at each of the three speeds. Two 35 amp bridge rectifiers were used to rectify the three phase output of the coils.

The results were pretty good and better than I expected. The maximum output in 'star' was 133 Watts at 480 rpm and in 'delta', 123 Watts at 480 rpm. I can't try it at any higher speeds at the moment as the lathe won't go any faster! Also at the higher outputs the lathe motor was struggling to drive the genny and the drive belts were slipping. I'll have to rig up a different test bed with a more powerful motor. Looking at the figures so far I reckon the genny should be good for at least 200 to 250 Watts ( you were right Zubbly!)

Open circuit volts (DC) in star were: 23.2 v at 190 rpm, 41.0v at 320 rpm, and 64.7v at 480 rpm. In delta: 13.5v at 190 rpm, 23.9v at 320 rpm, and 37.3v at 480 rpm.

Now where's that 1 HP motor I've got lying around somewhere!

John