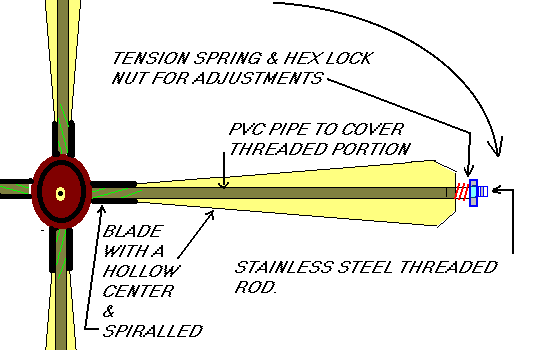

Yes, you are correct. As the RPM's increase the spiral base

wants to pull outward and thus changes the angle to a furl

neutral angle. The spring under tension trys to prevent this

action and will in accordance to how much tension is applied.

This would prevent high wind damage and produce a more

constant charging RPM.