Hi all,

Great forum!

Wondering if someone can answer some questions I have.

I want to create an alternator with maximum charge output at a minimum weight.

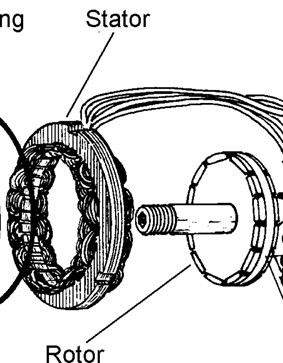

Looking at a commercial wind turbine alternator (see picture below), it has the magnets on the rotor placed vertically and the stator has the windings vertically as well but with layered metal placed behind it.

Is this construction more or less efficient than an air core solution with the stator horizontally wedged between two magnets like most of the designs discussed here?

With a solution like this, would the stator winding setup be very different to an air core solution?

Realizing it would be quite disastrous using aluminium on an air core alternator, but would it create too many Eddie currents in a solution like this?

Thanks

Memphis66