This is a circuit I put together when I first started playing with the F&P smartdrives. I promised to give it to brucedownunder some time ago but could only find an incomplete scribble and the original board was long since scavanged for parts. As I am once again playing with the smartdrives, I thought it might be fun to put another one together. The circuit is very simple and is based on a picaxe 08M. I used parts that I already had but you can probably get away with anything similar. If I were to buy the parts I used it would cost around $NZ30 ($US20) including the picaxe and protoboard.

The smartdrive motor suffers from cogging and typically won't start up until the wind hits around 30kph (18mph), however once going it will produce power down to around 10. In an attempt to improve the low wind performance I built this circuit to give the alt a kick start. It operates by pulsing each phase in turn in the appropriate sequence to drive the rotor - much the same as is done when the same motor is used in an F&P washing machine. When used in a washing machine, hall effect sensors are used to determine the exact time to pulse each phase. Unfortunately to use this method requires either placing the controller at the top of the pole and supplyng it power, or running a number of extra wires down (I have actually done this as well, but thats another more complicated project...) This circuit requires a star wired alt with the centre connection brought down the pole as well (total of four conductors - maybe possible to use the pole as a conductor???). The magnets on the rotor can be in any one of 6 positions relative to the coils (3 phases x 2 poles) and this solution is optimised for only one of them. However this shouldn't be a problem as the other 5 positions still result in a 'kick', though not nearly as hefty. If the turbine doesn't start after the first attempt, the odds are that the rotor is now stopped in a new position and you get another chance. Obviously there's a 1:6 chance of hitting the sweet spot in any attempt. The kick when applied in the correct rotor position will result in more than one full turn of the rotor (hopefully a lot more!!) The 'kick' is triggered by closing a normally open switch. At this stage I have not tried this circuit on a turbine in actual use. My intention was to use a 'gust gauge' mounted on the tower to activate it. One way to make a 'gust gauge' might be to suspend a ballcock lever (round plastic ball on the end of a brass rod used in troughs, cisterns etc) in the middle of a suitably sized electrically conductive ring. The ballcock arm is free to swing in the wind and can be adjusted by adding weight (maybe sand in the ball?) When the wind blows sufficiently enough to move the ball and make the lever touch the ring, the 'kicker' is activated. Suitable delays can be implemented using the picaxe to ensure the kicker only tries once in any one gust and doesn't try to kick while the wind is already sufficient to turn the prop etc.

Here is a schematic showing the actual components I used:

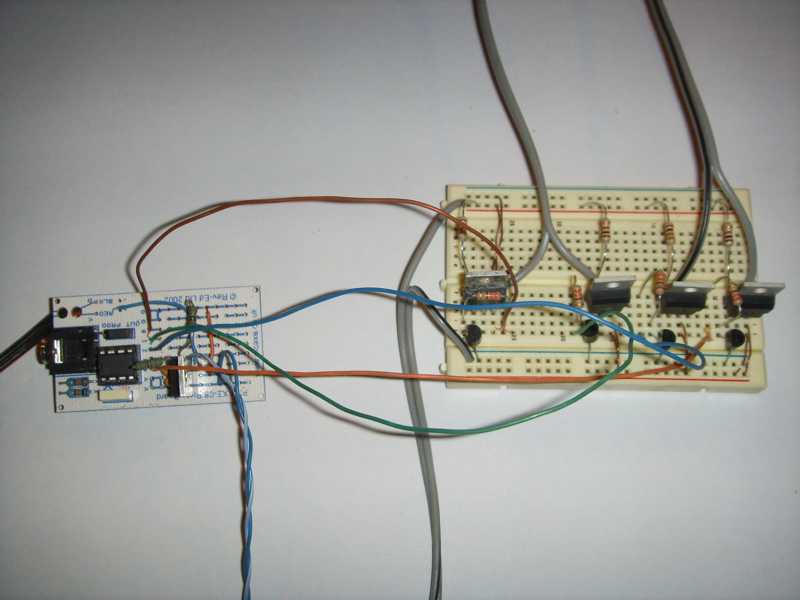

Here is a photo of the actual circuit:

Here is a video of the "kicker" in action (~1Mb):

http://www.otherpower.com/images/scimages/2210/FnPKick.AVI

Here is a scribble showing how the kicker is connected:

Here is the picaxe code I used in the video:

http://www.otherpower.com/images/scimages/2210/FnPKick.bas

The pulse durations and delays were derrived experimentally and are probably unique to each setup. I stopped when I achieved one complete rotation but there is nothing stopping you from going on finding pulse/pause lengths to get more 'kick'. The only limit is the program memory on the picaxe.