Sorry Merlin, I was thinking of something like this.

I'm no good with the drawing aspect, so here we go.

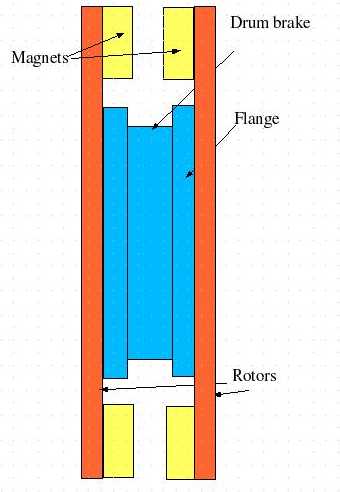

Perhaps use the drum as the rotor carrier, this gets rid of the first 12" of rotor disk steel x2...in your case 12"x 1/2" x2 of solid steel not needed to carry

The flanges can be rings welded on to the drum and machined to a true surface to face and bolt the rotors against.

The front of the drum (1/2" steel) would support the bearing carrier (welded to it using heavy pipe of whatever diam suits your bearings and machined out.)

This is simple, strong, and allows the brake drum to perform all the hub functions as well as be a drum brake.

This requires some decent machining, but this odes not appear to be a problem for you. You have to be able to deal with the 12" pipe/brake drum fabrication anyway, this just add a few more steps.... and much stronger and no rotor warp is going to happen here, so can use thinner (5/16) steel for the rotors. ( assume you were shooting for 3/8 or heavier for these if only stud mounted)

what do you think?

.............oztules