Hey All,

In the quest to build lower resistance and higher amperage output coils I've noticed several of you have started using 2, 3, 4 or more "in-hand" coils. I like that idea, and also sharing coil space among various wire gauges of those "in-hand" coils.

What about this?

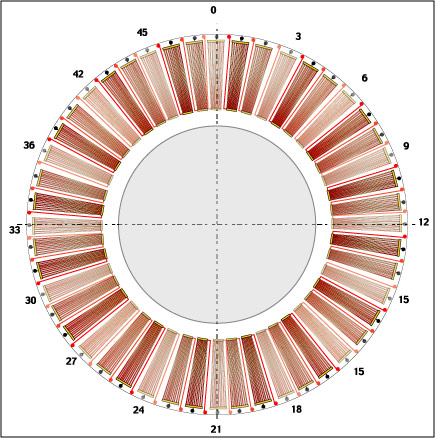

How about solid plates on the ends of the "coils" with straight segments of wire laid up in neat little rows touching the plates at each end. A layer of thin wire, a layer of electrically insulating substrate, a layer of thicker wire and another and another so on and so on. I would think soldering each layer would be a pain, but if ends could be left out of the coating/enamel a single row could all be joined as a unit.

Maybe make a jig to clamp the row of wire flat, burnish the ends, and solder on the "caps".

Would it be possible for some liquid to be highly conductive and cure to a solid, say when exposed to high intensity UV? If such exists I might be able to screen print these onto mylar or mica or??? and just keep stacking them layer upon layer.

If a single "span" line broke or burned the whole "span" might not fail.

Even if a human did/could splice thousands of ends that human might go insane. Some methods to automate laying the wire already exists. Small motion welder or whatever.

Width or "span" of these coils could be varied to fit your type of magnet(s), thin wedge magnets to match these "coils" would be a pain to find. I just went nuts with the idea. There could be far fewer "spans" for thicker/wider/longer magnets.

So,