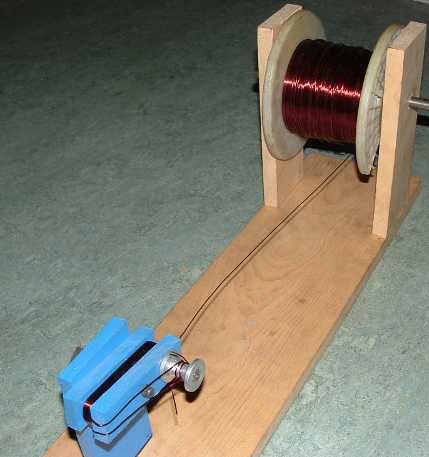

I built this coil winder from pieces of puck board.

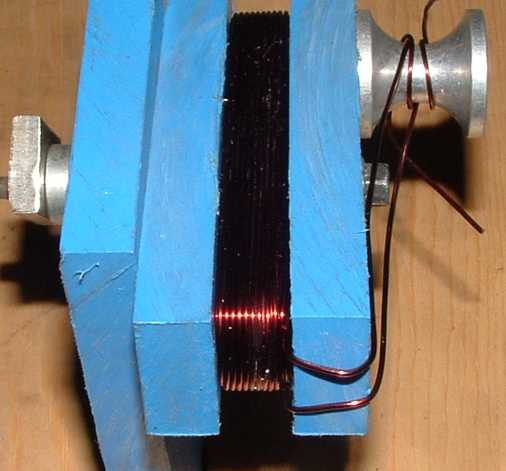

The next picture is the first test coil 40 turns. I used instant glue to hold the wires together.

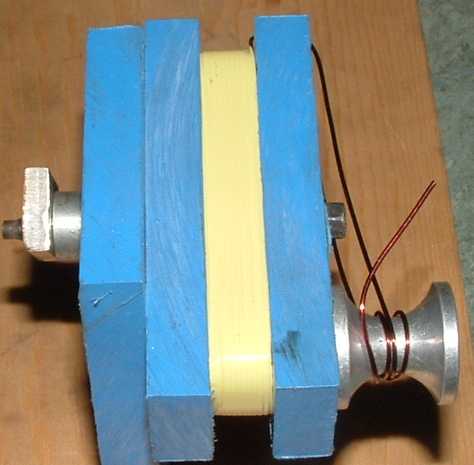

Then a 1/2" mylar tape was added to finish the first coil.

The winder was disassembled and the coil was presses out. The instant glue did not bind to the poly puck board and the coil was removed easily.

The first test with this coil and 2 magnets at 250 rpm was 1.5v at .79 amps. Now I have to construct 17 more.

Joseph.