Hello all, Spent the better part of the day traveling to town. I was able to buy the glue that will hold the displacer piston. It's called "Ultra Copper" and what I found out is it can work up to 700 degrees f. That is two hundred degrees hotter than I thought. Should work.

Started working on the piston and displacer connecting rods. Here is my first attempt.

This one is cut from .200 inch brass plate and the xyz cuts it out in a single path. Two small screws hold the collar to the rod and I found the unit hard to work with. Scrap that one. Back to the computer and a redesign. The computer program is Easy-Tracks and the change is simple.

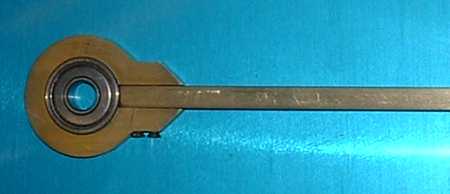

This picture shows the new design of the bearing collar and connecting rod and the displacer connecting arm made yesterday. The two small screws holding the collar to the arm were upgraded to a larger size. The bearings used are a Z type.

A side view of the parts. A second similar collar and connecting rod will be used for the power piston. I will keep progress updates. This seems to keep me working harder to get this engine done. :0) Bill