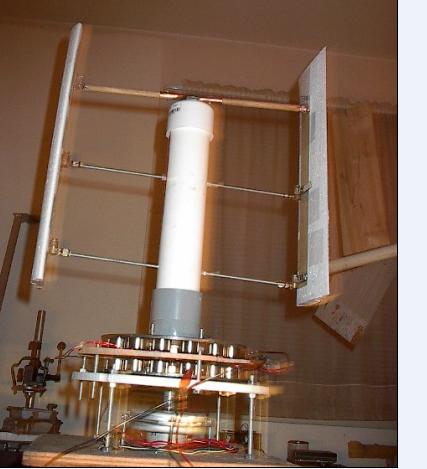

This is my VAWT from a couple of winters ago, reworked with Foam airfoils. A nice copy of Ed's cycloturbine if i do say so.

and hooked to my new Mini gen( one phase only)

it spins at 84 rpm in front of a fan.

this is held together with bubble gum and tape,minus the bubble gum , no hot glue ..yet

i just wanted to see if it would work better with lighter blades and more of an airfoil shape than the origional ones which were made of poplar, they were kind of sad looking really.

at this point i'm wondering just how large of a chord i could stick on there.

i had to make a special holder to hold the blade as i was hot-wireing it.

WXYZ should sell the origional blades as VAWT blades ( no taper or twist required)

i also used two layers of fiberglass to connect the supports and the top bar to the blades.

i held the offset (pivot point) in place while testing , i had an idea let the whole machine rotate on a base under the base shown,that way a holder could be made for the offset , since its position in space is constant, and the offset holder could have as large of a tail as necessary

picture a cage sort of , three posts connected together at the top , holding the offset in position , but able to turn with the wind, with a large tail to pivot the whole works into the wind.