New years day 07 oddball going together. I built this unit to be part of my drip boiler unit project and to be driven by a heat engine. But, I also made the unit to be mounted on a tower top and accept blades if I choose to do so at a later date.

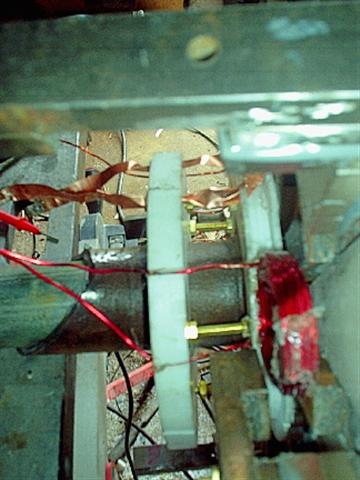

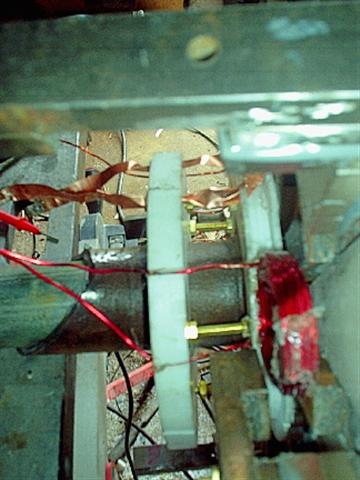

I started with a heavy hub and one and one quarter inch shaft from a lowboy axel that I paid $20 for so the hub cost $10 and the bearings were like new with no signs of ware.

I spun the rotor to above 1000 rpm, (after balancing) driven by a drill press (I will show the process in the testing phase) without the stator in place and had no problem with the high rpms or vibration. One test I am going to perform with this unit when it is put back together is to increase the rpms to above 2000, for an extended amount of time, to test the strength of the unit and also the amount of heat in the stator. Notice my supervisor in the lower right corner of the picture keeping an eye on things to make sure that I didn't screw up the test (she likes the wind blowing in her face and I trust the strength of the machine). The wind coming off this thing is just like a fan would work with regular blades on it and the flywheel efect of 80% of the weight of the rotor on the outer rim, keeps it spinning long after the power is cut.

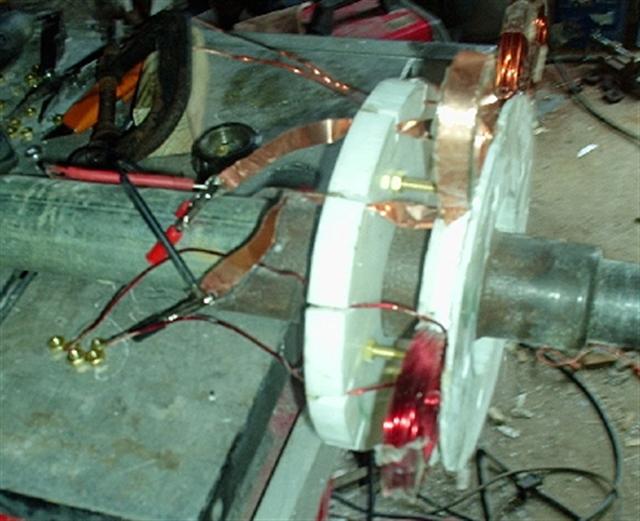

I have installed three different test coils for the first test, including the flat ribbon coil, one fifty turn #13, and a seventy turn coil of #14. I did not count the turns of the ribbon coil but will take it apart after the test to count turns and weight copper.

I have given everything a coat of fiberglass rosin and will give the entire unit two coats of auto paint to protect the gen from the weather and I will put a shroud of thin plastic around the rotor as well.

The air gap can be adjusted by two different sets of bolts, one set of bolts adjust the location of the stator in the air gap and the other set of bolts adjust the total thickness of the air gap. The next step is to put the unit back together and do the coil test, wish me luck and any comments welcome pepa.