I've been in the process (time allowing) of building one of Hugh's 12' Wind Turbines.

It's hard to believe but I haven't done much since last winter. Anyway I thought I would share my progress with everyone.

This is a shot of 3 of the coils; 25 turns, 2 in-hand, #13 wire. These coils where all wound with my "Mean Coil Winder".

After all the coils where wound I prepared the coils for soldering by burning a portion of the enamel on the ends of the coils, then cleaning the burnt enamel off with some emery cloth.

After that, they were placed in the stator mould and using a 1/4" piece of soft copper tubing crimmped together.

The crimp held them in place long enough to take them back out of the mould then solder them together.

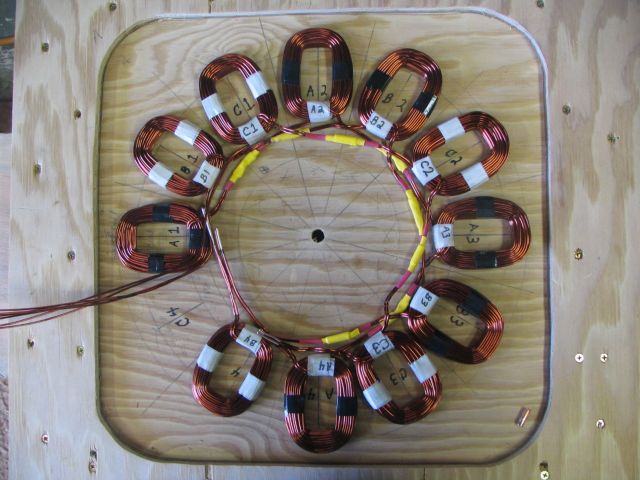

Here there is only one coil left to place in the stator.

Now they are all in place and the only connection left is to solder the end of all the phases together.

I held all the coils in place with this leftover piece of plywood, while I was glueing the fiberglass mat on the coils.

A dry-run in the mould and then it was time to mix and pour the resin.

The casting, although a little rough in the upper left corner came-out ok.

Next time I will have more filler material ready. I didnt really have much except a couple bottles of baby power and some left-over strips and pieces of fiberglass mat.

Well, that is the stator. I'm going to post more pictures of the frame, magnet plates and then the alternator's assembly.

Wil