Making this rotor was a pain. It is 4" in diameter and the magnets are N42 1x0.5x0.25 so you can imagine how packed are them in the rotor. The base I used was a 4" cutting blade from home depot. I know the it is not ferromagnetic but since it was suposed to be a small alternator I did not mind too much.

The process was extenuating check the picture below:

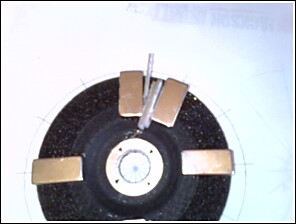

Since the magnets wont stick to the surface of the cutting blade I had to epoxy them down and keep them separated with cartboard. The pulling force between them was incredibly great so I had to be careful with my fingers and with them crashing together. It felt like if I was fusing a bomb. After a FEW hours I finished positioning the magnets in their respective places. They where so close together that I had to put resin so that there would be no casualties (magnets flying off).

Note in this picture that in the inner part of the rotor the magnets are almost touching each other and that at such distance will cause **SOME** field cancelation. And please note the use of the word SOME. I think that the smallest rotor that you can make with this design would be 4.5" with the same magnet size but that would bring an increase in size of the stator.

Ohh dear once again I am letting the resin cure without baking it and its craking again. I must be using too much hardener or something. Here is the Picture of the rotor.

The crack cant be seen in the rotor right now but I will have more pictures once the resin have cured.

I will be testing the performance of this thing tomorow morning I will keep you posted.