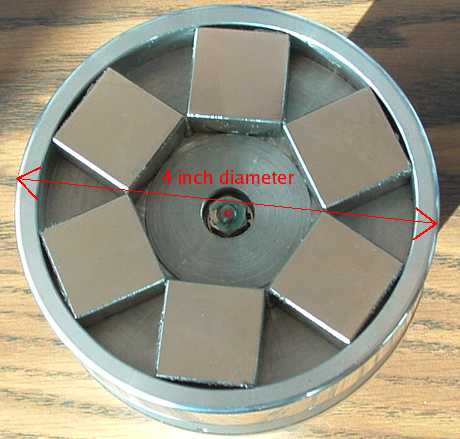

Made from an old 4" Sony VTR head that has been begging to be put back in service. I did some drawing on the cad program and discovered that six 1x1x.5 inch N48 neos fit perfectly.

There is a machined 1/4" steel backing plate added behind the magnets. The plate also builds up the height flush with the top ring. A close up shows the spacing between the magnet corners.

No machining of the head had to be done so the initial balance was retained. My first tests on this setup at 7200 rpm ran smooth as glass. I will do some coil design tests with the head this weekend and post the results. This last picture is a side view and the head spinning.

Now to wind some triangular coils.

Joseph.