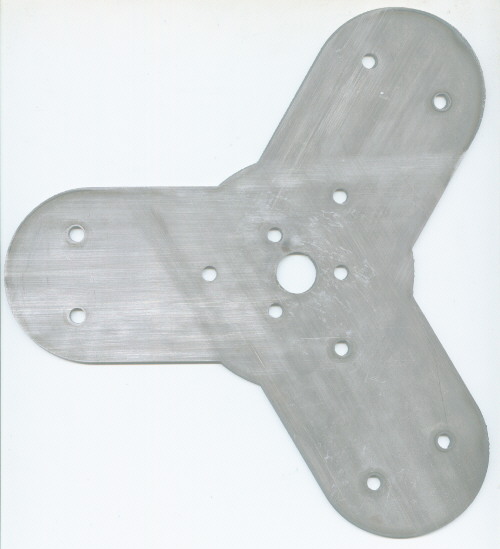

I designed these hubs and had them CNC cut from 1/8" plate steel.

Y, because 3 blades are best, and we need hubs.

The Doughboy 5, when you want a bit more than a 3 blade set.

NTL SUPER 6, The Daisy, functions as a 2 blade, 3 blade, and 6 blade hub. For those that want 6 blades or would like to try various number of blades.

The Magnificent Seven, a great movie and a great hub for those wanting 7 blades.

Comming soon, 2 blade, 4 blade hubs and for myself a few 1 blade hubs for fun.

The following is for the 3arm Hub but basically the same for all hubs except for extra holes. Subject to change, future hubs may have 0.75 ceneter hole, 1/4" holes maynot be cut at all, then I can drill any holes as needed any size in the same centered locations.

The hubs are 1/8" plate steel. The hub is 10"Dia., that is it fits in a 10" circle

From center of hub to tip the arms are 5" long

The arms are 3" wide

The end of arms are rounded with a 3" radius to remove corners or points that could gouge back of blades,

The radius also supports rear of blades better than a flat straight end

There is a radius where arms meet, prevents a sharp corner, adds strength.

The center hole is 0.68"-0.70" dia. (future hubs perhaps 0.75")

The 3 small holes in center are 120 degrees apart, rotated from arms to provide more room for blade root. (on 3 arm hub, others not applicable)

3 Center holes are on a 1.5" circle, that is 0.75" from hole center to hub center

The inner single hole in arm is 1.5" center of hole to center of hub (on 3" circle) and is centered in the arm.

The 2 outer holes are 1.4" apart center to center, they are 0.8" in from sides of arm, about 1.25" in from tip

There is plenty of room on this hub for additional holes if you need to drill more for your blades.

If you prefer larger bolts you can drill the holes larger, there is room.

These hubs will work well for many flat mounted blades, for blades needing mounted at an angle with a flat root you can slice a block of wood or metal at the mounting angle, sandwich the blade between the blocks and bolt securely.

For larger or heavy blades I would use 2 hubs one front and rear.

I had fun getting these made, more parts being drawn up for other stuff.

If we would have had computers and CAD when I took Drafting in Highschool I might have had a nice career