Greetings All,

Thanks to Pepa for the digital camera, and a few spare minutes from one hectic spring, I am presenting my larger and improved stepper motor minimill. There are 2 of these up and spinning, when the wind gods smile. I have one more yet to build.

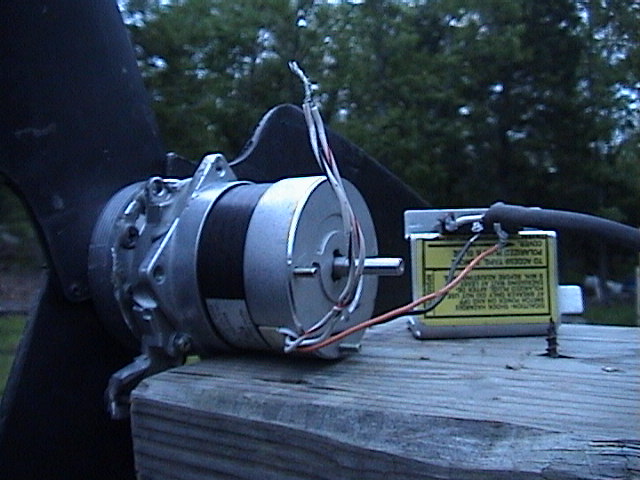

An old dead VCR provided the mount for the motor to base and motor shaft to blades. I just shot drywall screws through the VCR motor part disc into the blades. You will notice a couple dabs of JB Weld here and there to lock things down. The part the mounts the VCR motor to the frame of the VCR was used, after modification, to screw the motor to the wood mounting plate. I had to cut away some of the VCR mount for clearance, but otherwise was a good fit.

The blades are jigsaw cut from a plastic 55 GAL drum, then propane torch heated and twisted. I held them in position until cool and they retained the shape pretty well. They are 15" long by 3" at the root each. Blancing was fairly easy.

I series matched the 4 output leads and turned it into a single phase, and the rectifier from the VCR power supply is seen in photo 1 to the right, mounted on a small aluminum heatsimk. My past steppers, much much smaller motors, I rectified each phase and drove them with box fan blades, seen in the background of picture 2. These 2 "new" stepper mills put out much more than the old versions and now none of them are flying. I also did away with the capacitors as these motors, 15V IBM 4 lead motors, come up to 12V~ charging voltage quite easily. These were salvaged from laser printers found at the local landfill.

So aside from time I have about $2 each in these machines and in a really stiff wind will produce about 2 amps each. In single phase they do hum real loud when cranking. I plan on experimenting with furling when I get more time, but as they are now they do not.

Having too much fun!