Boondocker,

You derserve credit for some of the more meaningful work presented on this board pertaining to the axial flux alternator. In particular, the temperature data is most revealing and gives us an insight to the problems with the cast stator.

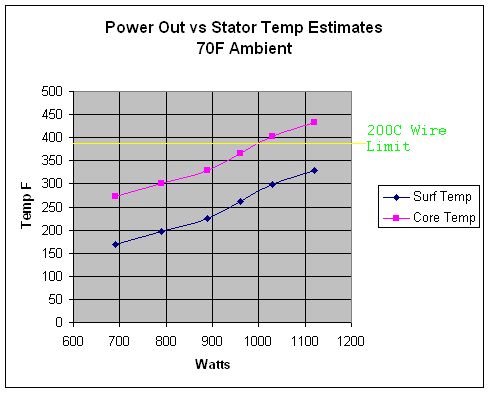

In looking at your data, one piece seems to be missing - the ambient air temperature. I assumed 70F in my analysis. This can be corrected for if significantly different.

Using your three power/temperature charts, the temperature rise over ambient gives gradients of 0.21, 0.24 and 0.34 degrees F per watt of stator dissipation. I used 0.3F/Watt in the following chart for the higher power levels.

The estimate for coil core temperatues includes a factor of 104F (40C) to account for the thermal resistance of the casting resin. The derivation for this is found here:

http://www.fieldlines.com/comments/2006/11/26/17291/409/27#27

Assuming 200C wire insulation rating, that estimated core temperature point is reached at 1kW output (760 stator watts).

Perhaps a more significant question is what happens to the casting structural integrity at those temperatures. Most cases of reported stator failures include reports of stator contact with the magnet rotors.

I would suggest a maximum safe sustained operating power level of 800W for your machine. This allows for higher ambient temeratures and a safety factor. It should be pointed out that this could be increased by 25% to 1kW if a non-cast stator was used.

I often see said here that the stator will run cooler when installed on a tower and exposed to the wind. In my opinion, this will not be a significant factor because the air flow is ill-defined in that area and the shielding by the air rotor hub will prevent direct wind from reaching the important parts of the stator. I wouldn't count on it for much benefit.

Yes indeed, rectifier losses are a significant issue. This is why I want to use synchronous rectifiers with less than a tenth the loss.

One final question. Were these latest tests done into a resistive DC load, which you have shown, or into a battery bank? If you really want to see the alternator efficiency itself, better to measure at AC into a resistive load. Of course the final end results is better shown with rectifiers into a battery bank or better yet, into a constant voltage battery simulator.

Many thanks for your testing and reporting. We need to see more of this done here.