somthing I have kicked around a bit and needed to do to see results for myself.

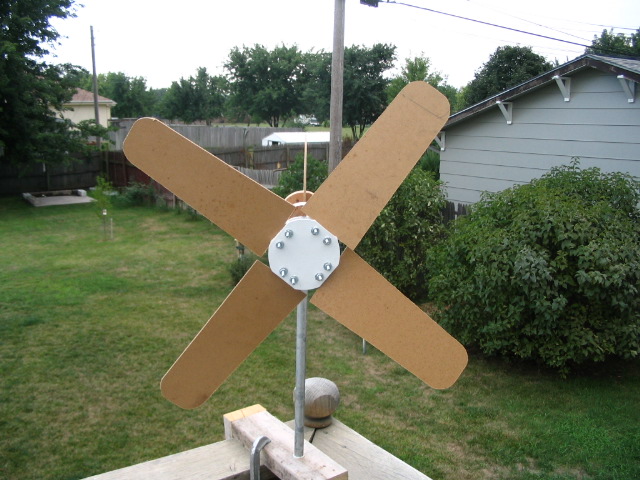

just actually some free hardwood scraps, some masonite or hardboard for tail and rotors, I actually do expect this to fail at somepoint (probably sooner versus later).

wide blade width to catch more wind, greater than >15mph to start.

hardwood supports jointed for more support.

at this point I made tail removable by slot, I may or may not secure it.

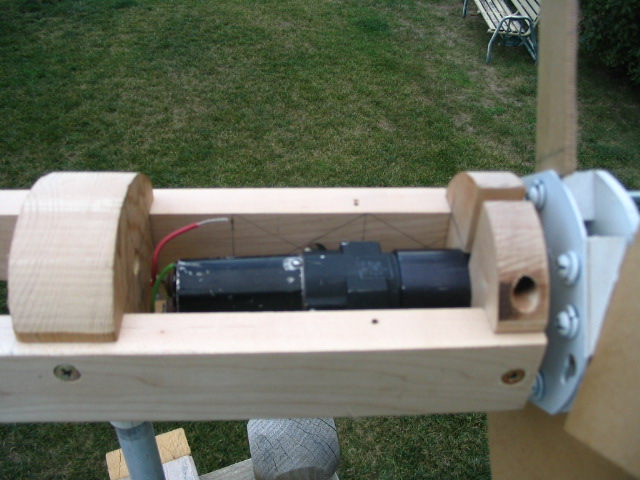

27.5vdc inline gearmotor at 200rpm, oz in unknown, but can be easily turned by hand.

I got to play with this the other day at 15-20 mph wind gusts. As I stated greater than 15mph to start. You can hand crank this as it sits to 24v, but shorted amp is unknown at this point and time - but, not to say it can achieve >24v with wind. Total cost thus far is about $13.50

probably a complete waste of time, but fun

oh, it is designed for a 4" piece of pvc tubing to slide right over the whole thing in case it isn't obvious.