Ok, here are the tests for my boost converter. First of all I will clarify that it is running at 100kHz and the output diode is a fast diode with forward voltage drop of 0.7V. I started using a 14uH inductor thinking that it would be the right value for the input voltage range expected, but it turned not to be the case.

Bad connections I know but the tests were made with #8 wire for the input.

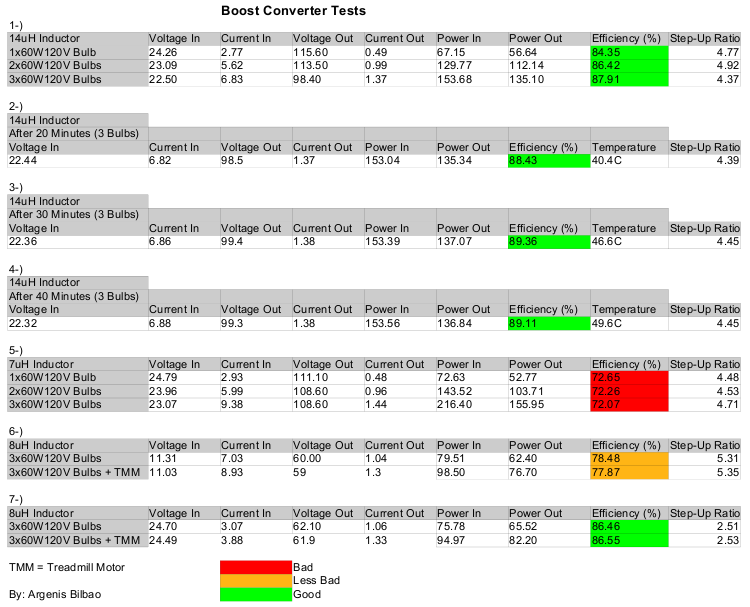

As I said before in my writeup Here, using too much inductance would cause low output currents. The tests (chart number 1) show that this is true but it also illustrates that using too much inductance hurts the converter's transient response. The output voltage started at 115.60V and as load was added to the output, voltage continued to drop. With only 3 60W 120Vlight bulbs the voltage was down by 17.2V.

Click on the picture to get the PDF version.

The good thing about having bigger inductance is that efficiency remained very high even though the Step-Up ratio was relatively high. It might work well in situations that the load will be constant.

Looking at the results I decided to cut the inductance in half. With half the inductance the efficiency for the same test dropped enormously as seen in chart number 5. On the other hand the transient response was great. The efficiency drop was an expected situation because the step up ratio is very large and the input voltage was relatively low. Better efficiency can be achieved by using 48V and the same Step-Up ratio for example.

Then I decided to use 12V nominal input and 60V output for then next test. With this one the Step-Up ratio was the greatest but the efficiency was higher than in the previous test because I increased the inductance to 8uH. This value seems to give the best transient response and efficiency.

The same test was repeated at 24V nominal input and as expected the efficiency rocketed. Looks like 90% of the job at building this type power power supply is to find the right core material and inductance for the desired operating range. After all the tests it is obvious that running the boost converter in normal conditions eg (12V to 24V, 24V to 48V) would yield efficiencies over 95% easily.

More tests will come later.