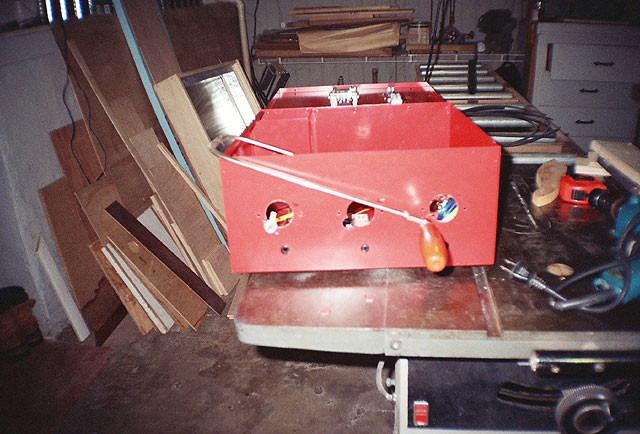

I bought a surplus emergency lighting box for $17. It's 15" x 15" x 7" deep with a locking slide bolt to prevent unauthorized access. In the photo below I have used a hole saw to make three holes so the rectifiers could mount directly to the CPU heat sinks. I also notched out each hole for snap disc that control the fans with a fret saw. It's nice to have nothing but woodworking tool when you're working with metal!!

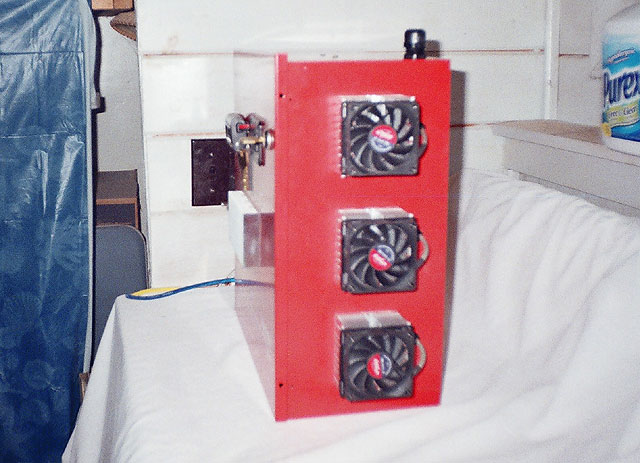

Here below, the fans have been mounted and wired.

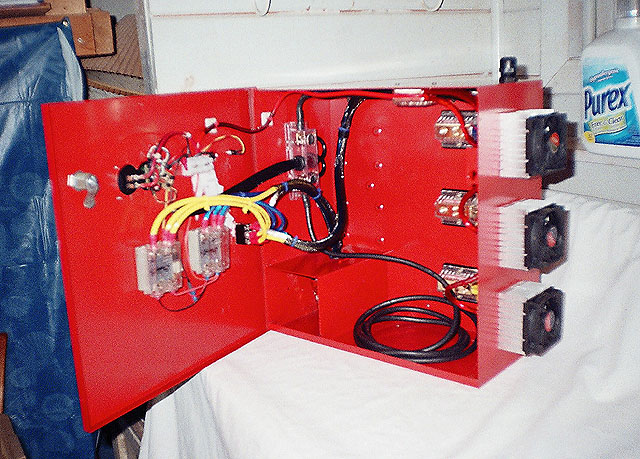

In this front view of the control box below, the little black dot (top left) is a push button switch ON - (OFF) for a resetting the "Doc Wattson" meter (top center). ( ) means momentary, for those who don't know.

The small black panel (top right) is a retro- fit for Ghurd's LVD \ Dump Load Controller, with it's own toggle switch built in and two holes for the LED's, labeled input and output, already!!

The big DPDT (ON) - OFF - ON toggle switch (bottom left) is for braking, soft braking in the (ON) position with 0.2 ohm 300 watt resistors on each phase, and the ON position for direct short, for all stop.

The Heat sink (bottom center) for the Dump Load Power Mosfet and two SSR's, which are mounted inside on the door.

Below is a picture showing the wiring on the inside of the door. I'm going to remove the SSR's from the AC side and replace them with IGBT's mounted remotely near the dump loads. Not sure it will work yet!!

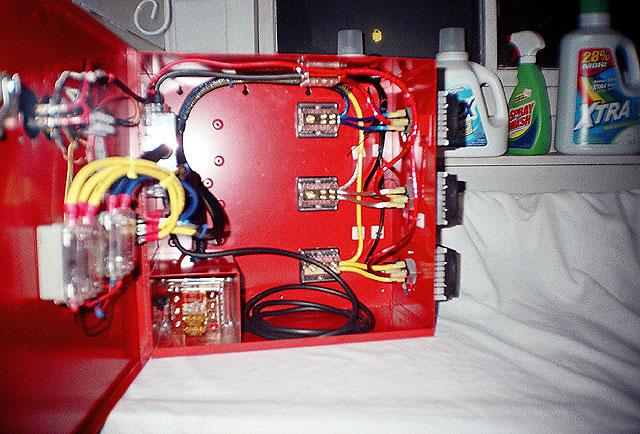

This next picture is the wiring of the rectifiers and fans.

The last picture below is of the wiring for the soft braking. The power resistor (0.2 ohm 300 watt), will be mounted off the side of the box. YES, I'm making a bracket that will keep them well away from the box and door!

Blessings, Snow Crow