Got the 48V motors on eBay. Thought they may be good for a tiny windmill. Wrong! 1200RPM cut in for 12V.

Gave them to my off-grid solder guy, who quickly put them to good use.

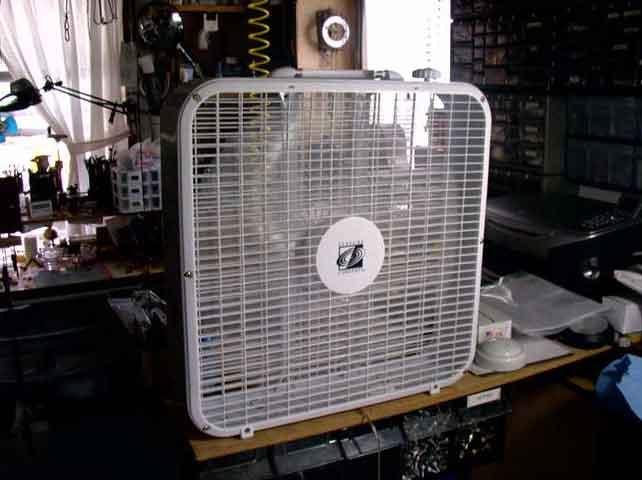

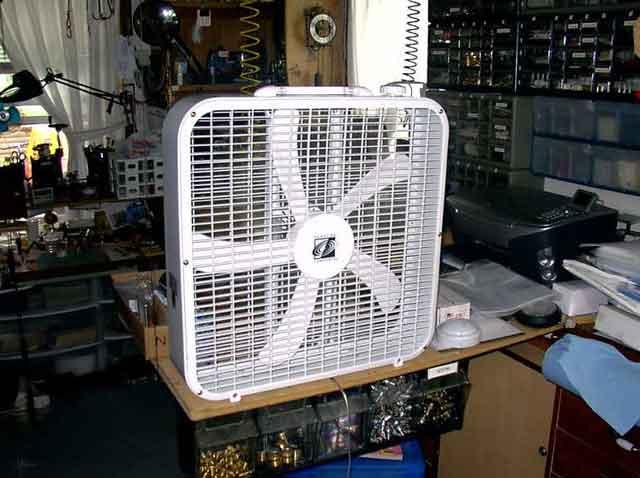

A couple L brackets and hunk of plywood hold the motor. The rear encoder cover was left on to cover the rear shaft.

The factory pulleys were turned down with a chisel, when the motor was running on 12V. Then sanded a flat to match the blade.

I think he used the factory switch. Not sure how he did it. The switches and motors are not like they were a couple years ago.

High uses 700ma, straight from 12V (13.5V at testing).

Medium runs through a 5W 8.2 ohm resistor, and uses 400ma.

Low runs through a 5W 25 ohm resistor, and uses 200ma.

Nothing very scientific about the values, simply had them on hand.

The power (speaker) wire is shown under the fan. The coil that looks like it goes to the switch is an air line 10 feet behind it.

It uses about double what the "$10" treadmill motor fan uses, but it fits in the case pretty well.

Running on High, through a 555 based PWM controller, adjusted to be about the same RPM as low, takes about 150ma from the battery.

The thing is super quiet! Almost can't hear it on Medium. "Silent" on low.

G-