This is the process I used in carving blades.

I used the plans in Hugh Piggott's book "How to build a Wind Turbine" for deciding

how many stations I needed and how to layout the lines.

I used the blade program that I got from Ed at Windstuffnow for calculating the length,

width, etc.

Thanks to Ed and Hugh for all their help and knowledge.

The blades are sized for an Ametek 99 that Birdmanjack needed a set of blades for.

We made a trade----I needed 12 inch diameter steel plates, and Jack needed blades.

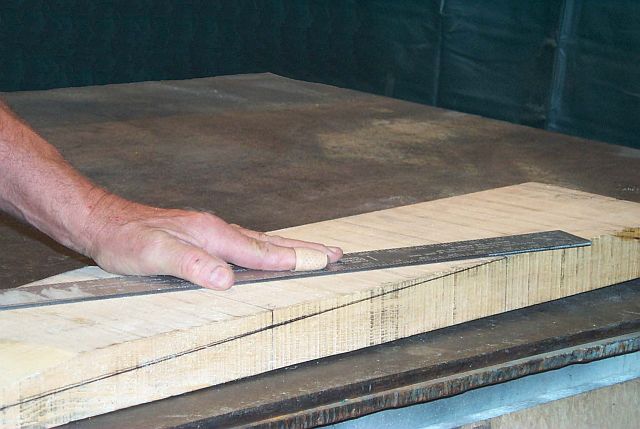

The first picture shows where the blade starts after all planning and calculating. (You have to figure out how much blade you need for the generator you want to build. Or you decide on your blade size and then build the generator to match it.) These are 10 inches wide by 1.75 inches thick and were cut for 5 foot length. (10 foot diameter)

The next step is after a little bandsaw work. I know the picture is sideways--

but that's the way my world is!!

Then layout the lines for contouring.

I tried all kinds of ways to get rid of the excess wood. Notch with a saw, then hammer and chisel to remove the waste.

Then use a hand plane to smooth it down.

I also tried using a device that attaches to a handheld grinder. (It is sold under several names---The one I used was called Arbortech.)

I also did the intense arm workout called using a drawknife.

Then the final tapering and smoothing was done with a belt sander.

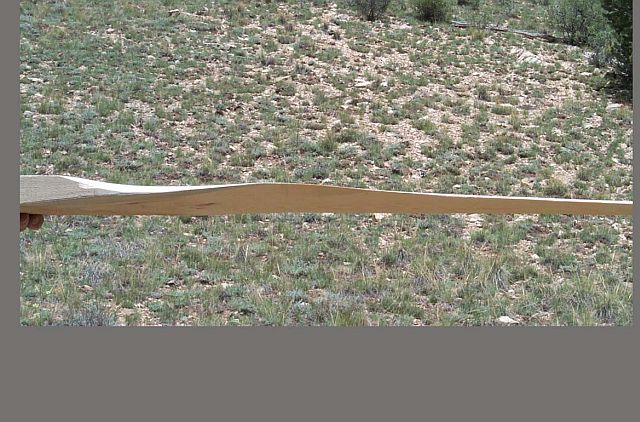

The final product after finish sanding is shown in this shot. It looks amazingly like a birds wing. Remember this was done using the instructions in Hugh's book.

But I can tell you for sure, the next set I carve will be done using Oztules great idea of trimming down the waste with a chain saw.

Thanks Oz. My arms thank you too!!!!

Ralph