Hello readers. Decided to make a diary entry about the summers progress. As always, comments and advice are welcome

This actually happened during early springtime.. Started by lowering the larger windmill. It's been a a few years since it ran, and along a new generator it is in lots of need for mainteinance. The blade diameter on this is 8.8 metres and the tower is 34 metres.

After disassembling, and stripping the paint it became obvious one of the blades had developed some rot in it.. All of them have now been drying for the whole summer, and I'm going to bring them inside for a proper new coating, and scarf new wood to the one blade with rotten part.

I'm going to (at least i'm planning to) use this 15kW 1500rpm slipring motor for a new generator to this wind turbine. It's gone through the same conversion process, as the broken generator(described here : http://www.fieldlines.com/story/2008/3/2/20410/91854), and it makes its rated voltage at rated rpm with 6VDC supplied to the rotor, drawing 12A. The old system used a modified car alternator to supply the field current to the main generator, and output was controlled by varying the small field current on the auxiliary alternator. For this, I'm thinking about ditching the aux generator, and try some sort of PWM control for the field excitation, from 12V battery. Power is going to be fed to 2x 6kW (400V) and 1x9kW resistors, located in the hot water tank. Drive for the generator will be through the old 15:1 gearbox, and propshaft.

The most labour intensive job so far has been stripping/repainting the tower. I'm only going to repaint the red sections this time, as the grey parts are not rusting up so bad yet, and will propably be good for another few years. So far about 2/3 of the job done, hoping for a few more good weather days (been raining almost all summer here :/) to get the job finished before winter.

The 12V 3.2meter axial flux machine has also been doing well. Before sowing season, i got the cable buried in the ditch. Intresting to note was, that after adding the longer cable(because i moved the batteries) it seemed to also lower the furling point of the machine. Now it starts furling at 30A, and peaks at 35A when furled about halfway. After that, output drops rapidly. Seems ok for me, as the battery bank is rather small, so it's most likely dumping anyway if it's producing 30+ amps.

I'm planning to take it down after the harvest to give the wooden tower another coat of tar, and also to inspect the machine for loose nuts etc.

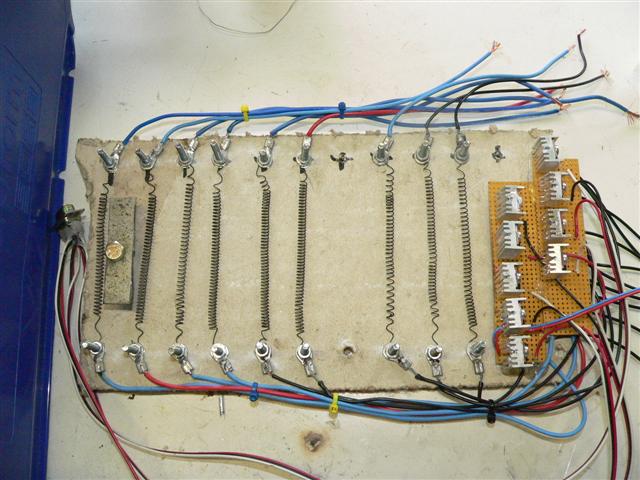

I also built a new dump load system for the axial flux wind turbine, to replace the crude on / off system. The resistors are Ni-Cr wire, stolen from a broken electric heater. Each of them dumps about 4.5Amps@14.5V, so there is some extra reserve if the turbine for some reasong might exceed it's normal output. I also made a nice steel box with fans for the resistors, but forgot to take the pictures.

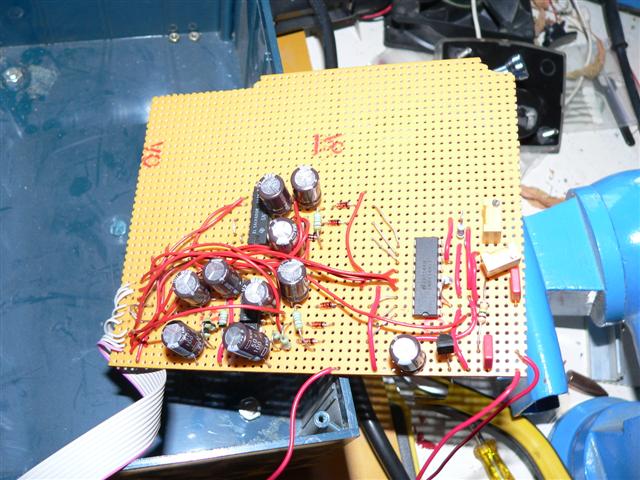

The LM3914 based controller looks crude, but seems to work ok, at least in bench tests. The schematic for the circuit can be found at http://www.anotherpower.com/gallery/My-electonics-stuff/uusdumppi?full=1 , i'll put it as a link, as it's too big to display here.

It's much like the controller designed by Amanda, just the delay part is a little bit diffrent. This one has no on-delay on the outputs, but has a few seconds of off-delay.

Anyways, that's the summers's RE progress here. Not much, but what can you do when work and stuff like that prevent most of the fun