I must say I'm very happy. I asembled the 14-11 PMA today.

All but the coils. This was to test the effect of placing a mixture of powdered iron dust/residue from a brake drum/disc laithe in the coil centers.

I mixed about 25%? iron dust with fiberglass reson into stator disc set up for 11 coils.

I cut 11 openings of 1-7/8" X 7/8" X 1/2". The 2 steel discs I'm using are 12" dia. X 1/4" thic. There are 14 ceramic magnets of 1-7/8" X 7/8" X 3/8" on each disc.

I have not wound the coils yet. This is simply a test for cogging.

I'm very pleased to report the cogging is extreamly small. All most none existant.

The shaft in this unit is 3/4" and at the prop end reduces to 5/8".

The stators spin very easy with just using my thumb and for finger on the 5/8" shaft.

I've stood below wind generators spinning up in the wind and have heared that distinctive growl from the magnets passing by the coils.

I hear the same but very faint sound when this unit is spun up at a high enough speed.

I can tell from this there is some atraction of the magnets to the iron.

I did a magnet test befor I assembled this unit.

Using this stator I placed a ceramic magnet on either side of the iron portion. They stuck.

I move'd the magnets away from the iron part and they fall off. NEOS would not fall off. There stringth would work and hold in a none iron gap much wider then this.

So I'm helping these weak magnets without introducing a detrementle amount of cogging.

Next I'll cut the test iron out of this stator form, wind the coils, cast the iron in the center of the coils and the reason over the top and outsides of the coils.

I'm wandering if there should be diferant wire ga. and turns count in the stator I'm building without the iron?

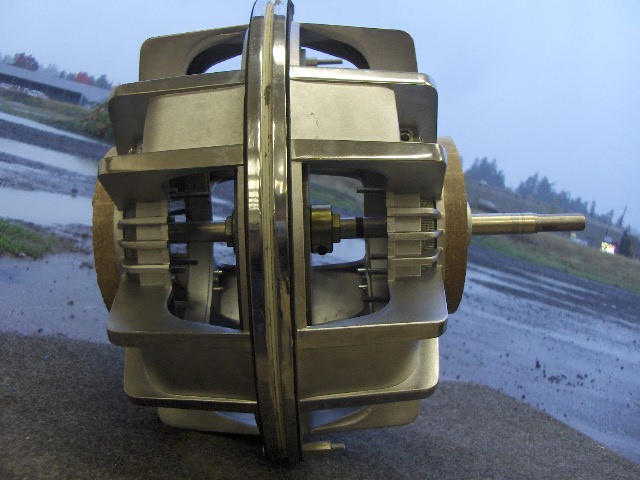

Here are a few picturs.

This is the front of the PMA. You can see the back side of the magnet disc and a magnet and the iron part in the staor just below.

Here is a closeup.

Here is a few veiws of the complete PMA.

Here is a picture of the stator unfinished. I'm test fittinf 4 of the 44 each 6 amp diodes the will be directly mounted to this stator .

More updates on the test #s soon I hope?

JK TAS Jerry