Alright, I have been lurking around here for a couple years now. I have been interested in building a wind generator for about 20 years now. Until I found this site, it was just a dream. At first, like everyone else, I thought I could hook up an automotive alternator to a set of blades, make tons of power, sell it back to the utility, and spend all my time at the casino on my revenue. Ok, maybe not that naive.

About the time I was ready to get started, we had a few financial setbacks which prohibited spending money on a science project. The advantage to this is that I had lot of time to read and research. About the time I was ready to get my feet wet in the RE business, I figured I would just buy a commercial small wind unit, making my own would be too hard. I even had one of those air-x units in my amazon.com shopping basket. After all, I these things start generating 400 watts as soon as you open the box. That word Naive comes into play again.

Right about when daylight savings started and I was staring at another dark Michigan winter, I commited that by spring, I would be the owner of a wind turbine, or at leas a heap of parts that reflect my attempt. This was also when I heard that there would soon be a book. I ordered the book between Christmas and New Years and started my project.

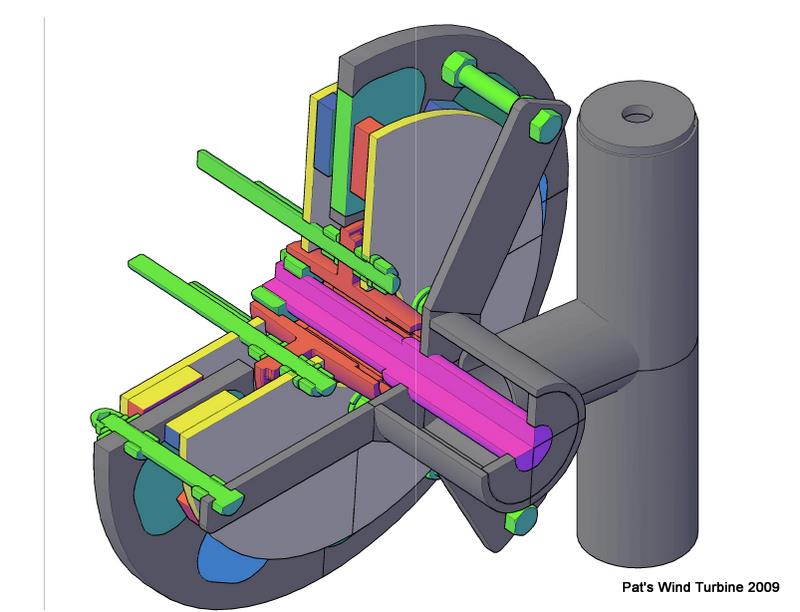

I have 20 years as a CAD designer. Instinctivly, I started modeling my turbine in AutoCad.

I have a nice shop to work in, but lack in tools, and have no metalworking skills at all. I have lots of mechanical knowhow and have basic tools for Automotive and Motorcycle maintenance. What I dont have is a lot of metal or wood fabrication tools.

My first hurdle, which I have yet to cross, is the Metalwork. I have a neighbor that builds machines for a living, so I showed him my plans. I gave him a set of cad drawings and he is working on it.

I built my molds on a cold Friday night and had my first reality check. My stuff didnt look anything like the pictures on the site. However, they should work.

The UPS man brought me a spindle, hub, and spool of wire the next week. Spindle and hub to the neighbor, spool of wire to the shop. I rigged up a coil winder, again, nothing like the pictures. The coils turned out ok tho.

After wiring and gluing together, I started to think about blades. Again, I thought about buying blades. Chinese blades are tempting. After a ton of research here, I decided to give it a try. The only thing Chinese about my blades is that I bought a $30 hand power planer from Harbor Freight. I couldn't believe how easy it was to make the initial profile. I finished with kerf cuts and chisel/hammer. 10 minutes with the belt sander and it's a blade.

I have prooven that I have the ability to make blades out of pine. I think I will take a look at making a set out of better wood. A friend offered me 1" thick x 10" maple boards he cut from a tree in his back yard. Can I glue a couple of these together and make a blade? Is Maple ok?

Last night was stator casting night. I have read a lot about mold release compounds. Wax, Turtle Wax, Candle Wax, Hair Spray, Axle Grease? Who would wipe axle grease all over the mold they just spend hours making? Axle grease it is! I was sure that I would be chiseling for hours trying to get my $100 worth of materials loose. To my surprise, it popped right out. A little dressing with a dremmel tool and this is what I got.

I thought I had spent a lot of time making sure my coils were aligned properly, but it is apparent that things moved around a bit. One problem was that after I soldered the coils together, I wished that I had a bit more clearance for the wires between the inner island and the bottom of the coils. I pulled and bent things around a bit. This must be when things moved.

Another question. I seem to have a lot of room between coils. The stator is wound for 24V, 70 turns of #14. In addition, there is one spot on the inner diameter where the copper wire is exposed. Should I attempt some kind of repair?

I am not too concerned as this is my first attempt and I believe it will work. I see a lot of criticism of workmanship, which I will take in stride. I believe that as long as you are doing something, "You Can't Do It Wrong".

The next purchase is a big one for me, Magnets.

Alright, enough for now.

image posting rules here are 640 x 480 pixels or less and less than 150KB not 800 x 600 pixels. it is OK for this time. just be sure to make your photos the right size next time

Kurt