This is my first attempt at both a motor conversion and a diary entry so hope it all makes a bit of sense.

Before I start I must first say a massive thank you to Ghurd aka "The Oracle" for all his hand holding and spoon feeding during this process - would have even less hair now without the invaluable help - thanks.

As previously posted my experiments with a Delco alternator came to a dead end and in pursuit of happiness I sought out a new project and was lucky enough to get my hands on a 1/3hp ECM Motor. I had done a lot of reading and referenced Jerry's posts numerous times but on opening the motor up still found it to be a daunting prospect! Anyway, came up with the following wiring scheme:

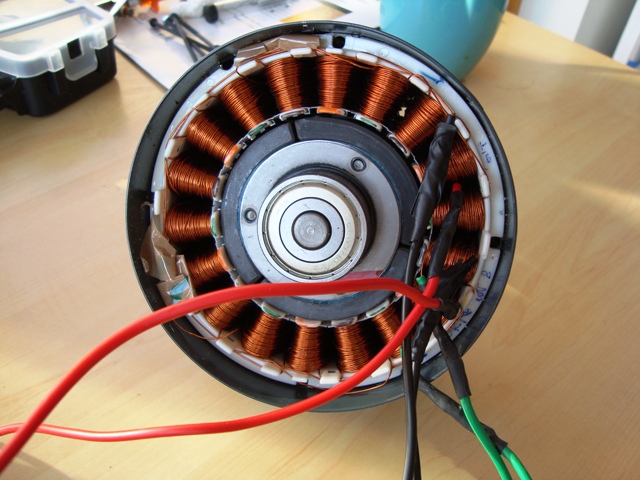

Wired the motor by attaching new wires to the factory "ends" having identified the phases and ran through three rectifiers. As this motor was going to be outside I thought it wise to try to weather proof. Some ali tape and several coats of enamel paint later the end result looked like this:

Having dabbled in pvc blades previously and experimented with wood blades I decided to stick to the wood method as reckoned I was getting better at carving so went for a blade length of 26", TSR7 and fed these figures into the Alton Wind Calculator to give me the parameters I needed ended up with rough blades:

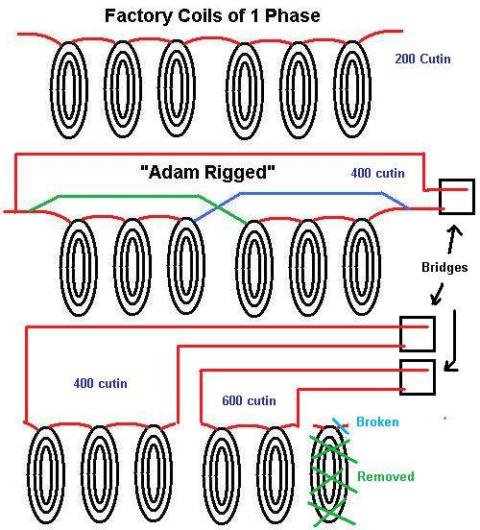

Happy with this as a starting point I put her in the air and let fly. The blades spun up well in a 8 - 10mph wind but stall was very evident, just would not increase in rpm despite increases in wind speed. With a little more spoon feeding I went back to the beginning. This meant seperating the phases further. In the process of doing this managing to break the end of one of the coils so had to amend my plans for the conversion again:

This is the format I settled on and repeated for the "black" and "red" phases but without the omission of one coil (as I had to in the "green" phase having broken one end!).

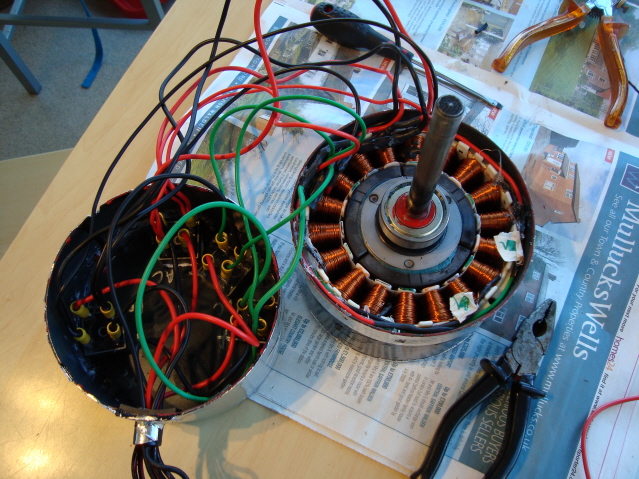

I ended up with the below as a ready to reassemble point:

With the finished blades, made from 2" x 6" rough cut pine, treated with five good coats of boiled linseed the motor, hub and blades were ready to be united and re-tested

I have a 10' tower in the back garden, close to the house so not a perfect site but open to farm land and the prevailing wind so not too bad either. Having waited the customary four days for some wind she began spinning up very well, in again 8 - 10mph winds with no sign of stall this time. I have the motor hooked up to two 110Amp hour deep cycle batteries and a Ghurd controller in my shed. I am not too good yet at figures so apologies to those who like the statistics, still learning and will post again when I get some. However, I can say that in a wind speed of 18mph the controller was dumping perfectly and providing I am reading my multimeter correctly I saw it peak at 12amps. I appreciate this may sound high but have double checked and seen this level on at least two occasions.

Anyway, I am happy, this is a good learning curve for me and at the moment if I can get charge into my battery bank and use this power to light my shed that is good enough for me while I continue the learning process and figure out (pardon the pun) how to get some meaningful data to post!

If this is a jumbled mess I apologise! G- Ta again!