Lots of pictures here, hope I don't upset you low bandwidth guys.

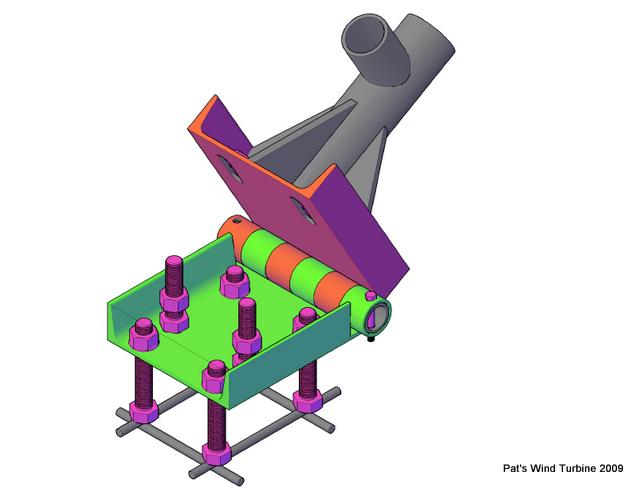

I have been busy building a 40' tower. In an earlier post, we talked about my design for a pivot mechanism.

I had 80' of 3" I.D. pipe donated to the project. (Thanks Jeromy)

The 3" Pipe has threaded couplers, I know we talked about how bad threaded couplers are, so we did a little reinforcing. 4" pipe is a perfect fit over the threaded couplers. I butted the threaded couplers together and welded the 4" to the couplers, and the couplers to the 3".

I want to thank Jeromy, Josh, Elliot, for their welding, and Kyle and Kurt for the welding, fabing and use of thier facilities.

It always helps to have equipment like this available.

One half of the tower base looks like this.

Went from 3" to 2 1/2" to 2", each about 12-18" long.

Used chain as a guy wire attachment. I have seen controversary about this, and wrapping the wire around the tower as a mechanical connection backup. Will have to see what it looks like once I start rigging. My initial thoughts are to run the wire rope thimble through the free chain link.

A little bit of painting

Got 3' screw in anchors at a 20' radius. Anchors were not used as screw-in, added/welded extra 6" lengths of rebar to the 36" long anchors and buried in concrete.

Poured a pad for the tower base. 18" x 16" x 30" deep. If you look at the cad drawing above, the 1" bolts are 8" long and welded together with rebar. The bolts were welded in the shop to fit the holes in the fixed half of the pivot hinge. I just pushed it down in to the wet concrete.

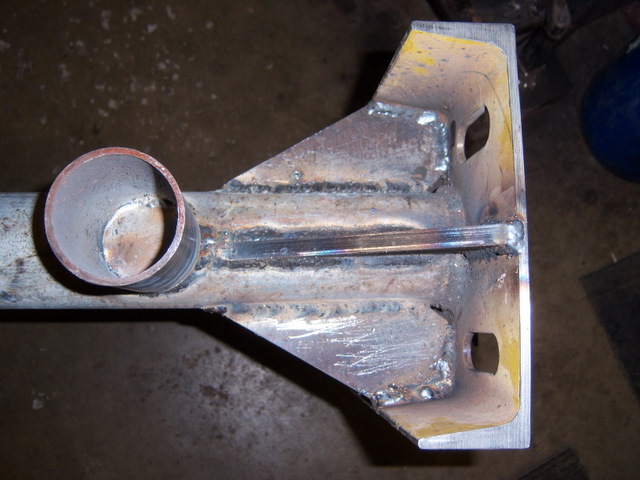

Here is the fixed half of the hinge

I am at the point where I need to let the concrete set for awhile. I have wire rope clamps, thimbles, and a couple pulleys on the way. (E-bay)

I am researching the forces involved in pulling this thing up. I have extra lengths of 3" pipe for a gin pole, but I am not sure I could stand it up into my gin pole socket I welded on the tower. I may use 2" for the gin pole, or just use a 10' length of the 3" instead of the full 20' length.

We are getting closer to getting this thing flying.