This is something i have been trying to improve for over 5 years, I think it's time to give up, Hugh Piggott told me as much, years ago.

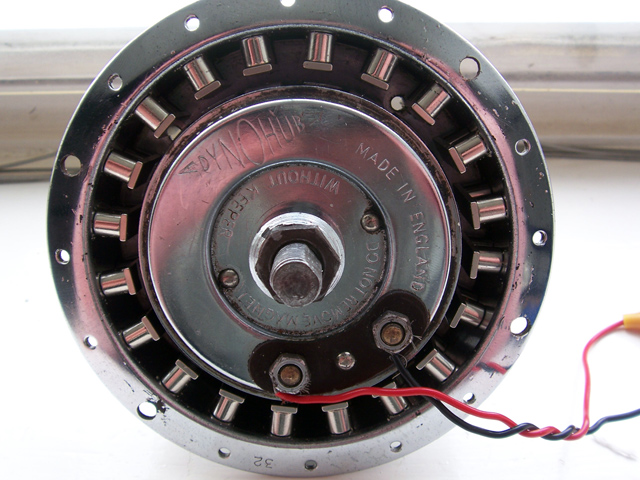

It's the bicycle dynamo hub, 'dynohub' made by Sturmey Archer in the U.K. shortly after the second world war - I don't think it has much of a presence in the U.S, although there are modern day variants, Shimano e.t.c

I put together a page on my website, just because I like it, and it reaches 6v cut-in at only 60 rpm.

http://www.gotwind.org/diy/Dynohub.htm

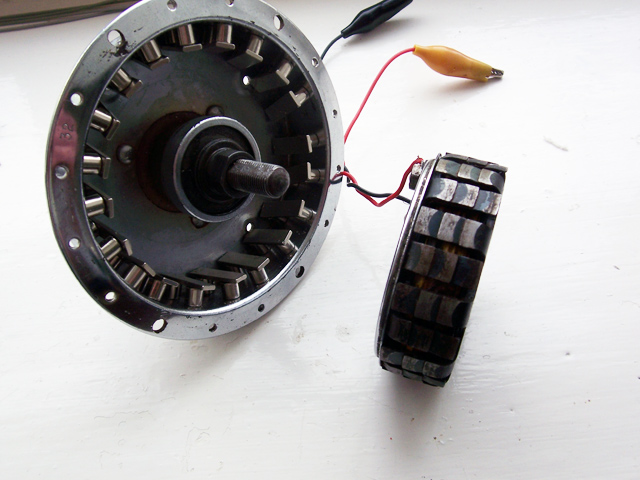

I have always wanted to convert the 20 pole ceramic ring magnet to a more modern Neodymium arrangment, the alternatot is a single phase claw pole arrangment.

Twenty N/S/N e.t.c N45 Neodymium poles were carefully arranged, and the stator inserted. The air gap was large, 3mm, but I don't think that mattered from my findings.

The cogging was horrendous, as expected, I was seeing a noticeable increase in voltage from the added flux, but the stator became saturated, as Hugh suggested, max current 0.5A.

I attempted to skew all of the magnets by approx 20 degrees to reduce the cogging, but it had little effect.

I think I will have to shelve my ideals of making the old dynohub into a suitable small wind alternator - It was good fun trying however :-)

Ben.