I suspect a lot of people have figured this one out, but it worked so

well that I thought I would pass it on anyway. IF this works, there is

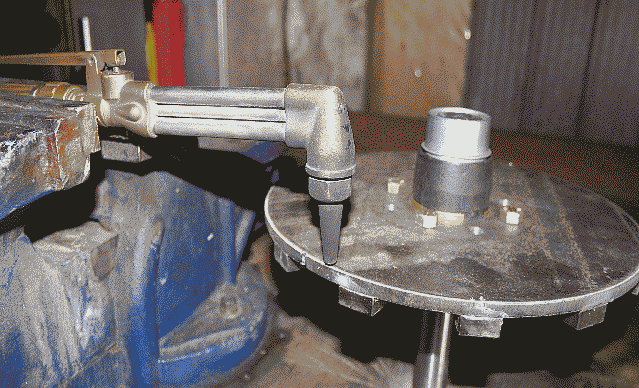

picture, but to word it, I tacked the spindle/hub on the welding table,

then mounted the rotor blank on it. I had already drilled the centre hole, and stud holes. I then gently clamped the cutting torch in the vice

beside the rotor blank. The picture, unfortunatly was made after all was

done, just to illustrate.

hope this works

bj