I've been fashioning test rigs out of sheet metal, which I've already been informed plenty of times is not the material of choice around here. And I used threaded rod for the pivot, which I also know was too light for the job. The long story short is the test rig had its pivot rod bend in high winds to the point where the turbine was pointing up in the air at about a 45 degree angle and turned opposite of the wind which made it spin at a higher rate of speed then when it was facing the correct direction.

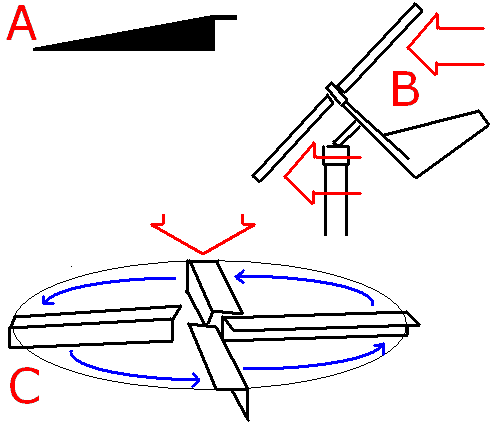

A = test rig blade design. I was aiming for hollow aluminum blade with a ten foot diameter, actually ended up closer to 11'. Basically a two piece construction with heavy aluminum forming a z-shape on the bottom and very thin aluminum cap that slid over and hooked onto the "z".

B = shows basically where the pivot rod bent allowing the turbine to tilt. The pivot sits atop a 4" water pipe and allows free rotation of the entire turbine. The tail is drawn out of proportion. The red arrows show the wind direction that began the counter rotation. The bent turbine seems to be gathering steam from some kind of ground effect.

C = shows basically the direction of the surfaces that seem to be creating the effect.

What is normally the front of the blade is actually acting like some kind of Lenz vertical wind turbine system, only it only seems to work effectively while in a steep pitch. Once straightened up it loses a lot of the effect. I haven't tried it as a pure vawt simply because I do not want to break anything, but tilting it lower to the ground so it is closer to vertical also has a negative impact on its rotation. One curiosity about it is that it seems to be less prone to slow down when its up to 20-25 degrees off the direction of the wind, whereas that normally tends to really slow down a regular turbine.

The blades are 6.25" wide by 1.5" thick, the dimensions chosen to fit the hub which is designed for mounting blades made from 2x6 boards. That extra .75" is the front lip of the "z" on the front of the blade. The original pitch was not optimized in any way, shape, or form; it is merely the slope from corner to corner. It actually has some 5" wide blade extensions at the root on front and back that taper down to the center of the blade just to increase surface area; it makes it start spinning in lighter breezes.

Going by handheld timing the blades rotate roughly 40% faster when put into the wrong position. I'm just curious if anyone has seen this kind of effect before? Its not really acting like what are normally defined as vertical or horizontal wind turbines. The effect seems more a hybrid of both.