Hi,

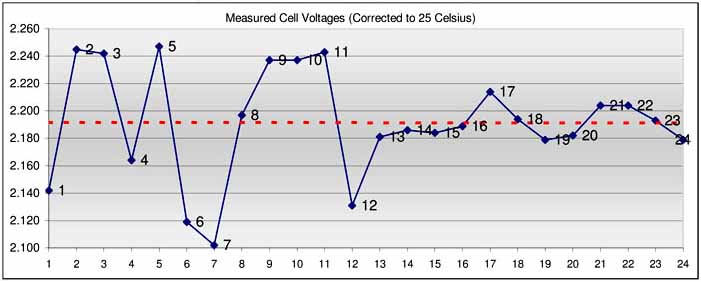

After bringing my bank of absorbed glass mat batteries gradually up to float voltage, I've had an opportunity to measure individual cell voltages while the charge controller keeps the float charge steady at exactly 14.0V. Interesting results follow:

(Click to see the input data - 141K JPG file)

Some of the readers may be noticing that the "corrected float" voltage (2.19V) is less than the manufacturer's recommended float voltage (2.25V). That's because it's very cold these days, and cold batteries must have their voltage raised higher and higher. However, there is a limit to how high the voltage can go. I'm not supposed to raise the actual cell voltage above 2.35V. Correct that from below freezing to 25 Celsius standard and it's not actually "full".

There is a fair bit of scatter in the cell voltages in cells 1-12, while cells 13-24 are much more consistent. Have a theory why, which I'll get to later, once I've described the banks in more detail.

The 24 cells are stacked in a 4x6 bank. They're currently connected in 12V, but once I've upgraded my inverter, I'll have them re-wired for 24V.

Stats:

GNB Absolyte 90A-11 Cells, 2V each

Each cell's 8 hour rate is 432 Amp-hours

6 Cells arranged together per battery (1-6) (7-12) (13-18) (19-24)

4 batteries total

Total charge is 1730 Amp-hours at the 8-hour rate.

At a more modest rate, the capacity is much much more.

(I still can't get over what a lucky s.o.b. I am for finding these.)

Before installing the batteries, I did a discharge test on some of the sets. I tested sets 13-18 and 19-24. I drew both sets down below 10V each using an array of auto headlights. Then I charged them back up using a 6A auto charger. Each cell is >400 Ah, so it took a really long time to drain and subsequently recharge them. I was satisfied after testing the two batteries, so I didn't bother testing the two other ones.

Surprisingly, it's the sets I tested that are much more consistent, now that I test their float charge voltages. So I'm speculating that I should un-couple the top two batteries for a while, and suck them down below 10V, too.

Any thoughts on this idea?

Does a deep discharge cycle do AGM's any good?

Can I read any meaning into the fact that the first and last cells are the bad ones?

Thanks!