What data do you have on the blades that you carved. Do you have any pictures? 69000 feet of board lumber? sounds like a lot.

photo of a small blade set I made a while back

here is the airfoil on that one looking from the end

the twist was not ideal, but this was basically very similar to DANB's post here, just drastically scaled down.

http://www.otherpower.com/otherpower_wind_tips.html#blades

Hugh Piggot has a large amount of data on blade theory on his website. Take a look at the blade theory pdf file.

http://www.scoraigwind.com/

Ed also has a section on blade design at

http://www.windstuffnow.com/

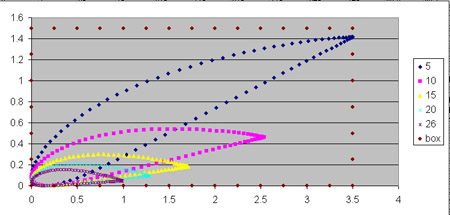

this is a plot I made and posted to my diary the other day using a program I wrote, which incorporates some of that theory for designing blades. I havn't actually used it to build a working blade yet though. The names of the curves correspond to the distance out from the center of the rotor. this was for a TSR 7 blade carved from a 2 by 4 with a 26 inch blade, or radius.

I don't know if the above will help you, but blades don't have to be perfect, they just loose a little performance the farther from ideal that they are, and since all designs contain compromises, an imperfection regarding the twist of the blade that hurts performance a high rotation speeds, might wind up helping with startup in low winds.

A simple mistake that I could see happening would be to reverse the airfoil profile on the blade. such that the front of the airfoil was used as the trailing edge.

Anyway, post more info if you have it, and someone here can likely help. Rich Hagen