Monday was kind of slow this week. I think we were still recovering from Scott & Bonnies very fun new years eve party, and George was sick with the flu so he never made it up. I did get a bit of work done on the new machine though. A recap - pictured above are the magnet rotors, 22" in diameter each with 20 magnets 3" long, 1.5" wide and 3/4" thick.

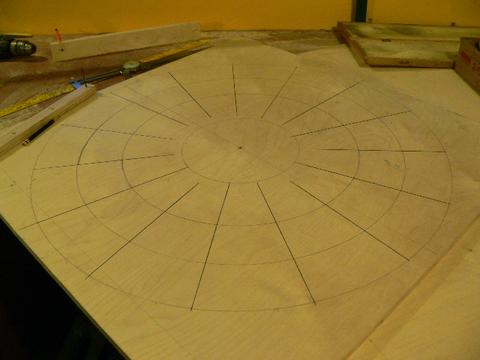

We're making the mould out of 5/8" baltic birch. The stator will be 28" in diameter, there will be 15 coils. I started by making a compass and drawing the circle on the board which will be the bottom of the mould.

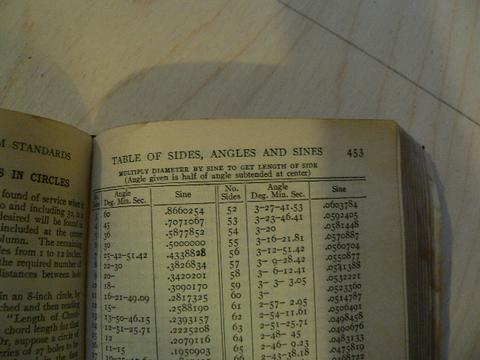

The machinists handbook is full of handy charts and information. This page explains how to divide the circle into 15 equal segments. Simple high school trig... but I forget all that stuff so I need to look it up.

Pictured above I've drawn lines. This isn't really necessary - if the coils are sized right and equally spaced everything would be perfect, but its handy to make sure the coils are the right size. It also helps me design the coils.

Then we draw two more circles so that we know the path of the magnets. When putting the coils in it's nice to know they're in exactly the right spot.

We used Scotts rotating table clamped to the bandsaw to cutout a 28" diameter circle for the 'middle' of the mould. It does a nice job.

There's the stator mould about finished up. Now we just need to glue/screw it all together. It'll be a big casting. In the past I've had minor problems with big castings cracking. This one I think we'll be very light with the hardener, use some filler and hope for the best.

It was a smaller party than average for a Monday. We ate leftovers from the party (no pizza). Fun as usual...