So far its been a good/busy fall. Pictured above is my 20' machine about half furled up. The alternator stalls the blades enough that I rarely ever see it furl more than this, which happens around 3KW. It was making odd sounds in high winds (sounded like maybe magnets hitting the stator in high winds when it yawed quickly). So last Monday (a week ago) we lowered it - sure enough the bearing was a bit loose so we tightened it a bit and re-greased everything/re-oiled all the wooden parts. The bearing was just loose enough that magnets could barely touch the stator. It's much quieter now and it's been good. The bearing was a touch on the loose side when we put it up origionally, and hopefully the additional loosening is a break in sort of issue. I hope it doesn't wear that quickly all the time.

I went to a crazy auction on Saturday. This was a neat little 1KW generator I saw there. There was way too much fun stuff there... I had to practice great restraint. Stuff seemed to go at very low prices.

A whole trailer load of magnetos.

There were 3 vertical steam engines there and two boilers.

They even had some old wind chargers. They looked to be needing a bit of work...

Just what everybody needs. This is a 50hp 2 stroke Superior engine. I believe it sports a 12" bore and a 24" stroke. Pretty awesome engine.

This is a Witte 5KW generator. The engine is an 8hp slow running (about 800 rpm) diesel - beautiful. I sort of kick myself for not bringing this home - I expect somebody got this for next to nothing. It had very little compression, it obviously needed work.

This is a nicer version of the same thing, a 5KW Witte diesel light plant - this one ran fine. I bid it up to about $700 - another fellow got it for just over that. A very good price on an incredible generator in my opinion.

There were a few other neat old engines there...

Yesterday Shawn came up to start his own 17' wind turbine. We're building it similar to my old one, but slightly larger magnet rotors (18" dia) and a slightly larger stator (of course) - and a larger bearing/hub assembly. Pictured above he's cutting out the stator mold.

This is his hub/bearing setup. It's identical to the one we used on my 20' machine. We got this from southwestwheel.com - ordered it last Monday, it showed up within 3 days. Impressive service and good prices.

This is an old wincharger I won at the auction. I expect its a 32V machine but Im not sure yet. It does motor nicely on 12V so I expect its workable. I don't really want it though - I'll probably send it on ebay or something.

Other treasure I won... this will be a lot of fun. I've always wanted to mess with this stuff but it tends to be expensive. It's completely rebuilt best I can tell. It motors slowly off my small air compressor.

It's a 6hp steam engine, built in 1903. I also have an appropriate boiler lined up I think. Although I've always wanted to get into this bad habit - the cost has always been prohibitive. Now I'm in trouble... this engine cost $140 - I couldn't help it. Perhaps we can get all this together by next summer.

$25 got me the wincharger generator shown a couple pictures above, and a few other parts. This is an interesting air brake - kind of like variable pitch blades but these are just paddles that flatten out at higher rpm to keep the speed down.

I also got this air brake. The wind turbine we made last spring with the 11' wincharger 2 blade prop and the airbrake has actually been really well behaved even in very high winds - it's been running down at Scotts since May. While I prefer the furling tail - the airbrake is a reasonable way to go I think and it's fun, and it looks neat! (they are a bit noisy)

Other treasure I aquired includes a nice old Farmall H tractor which needs a touch of work but seems to run fine. It'll be nice for a variety of things - including a good test stand for alternators.

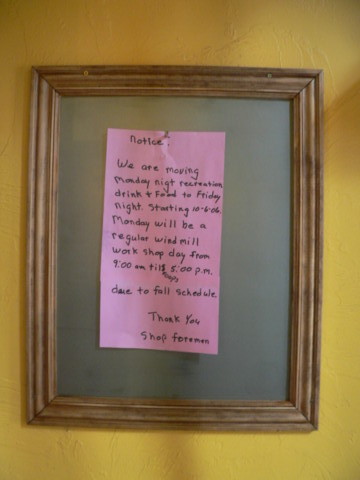

Enough said... last night was the last 'Monday party' - from now on we close the shop at 5:00 on Mondays and the party moves to Friday.

There's Shawns mold finished. This stator will be 5/8" thick and 22" in diameter. The island is 9.25" in diameter.

Shawn winding coils. We stuck with the same number of turns (68) as we did in my older 17' machine, and we wound with two strands of #15 gage wire. We made the coils a touch wider though, since the magnet rotors are larger in diameter.

Rich brought fire works...I guess this combination is all the rage now after something everyone (except me) saw on television recently.

You have to quickly drop all the candy in the diet coke and then the whole contents of the bottle come out quickly. Pretty entertaining.

Maya turned 9 yesterday.

Pictured above is Maya sitting on the Giant Pumpkin she grew at her grandmas house. This could've gotten much larger had we started it earlier and had the frost come later. WE got the seeds for this from Zubbly... (thanks Zubbly - next year it'll be bigger!)

Next week well have Shawns stator finished. We also got all the coils wound to repair my own 17' machine, so we should hopefully have that back up and running soon.