Last week I was running my 17' wind turbine in low/moderate winds, it was producing some nice output with about 1kw in a 15mph winds.

Did not expect it, but at 4:30am the wind kicked up considerably and for about a half an hour turbine output went up to between 3kw and 6kw. By the time I woke up and heard the wind and managed to throw the contactor switch it was too late, and it appears that the stator had been developing a short.

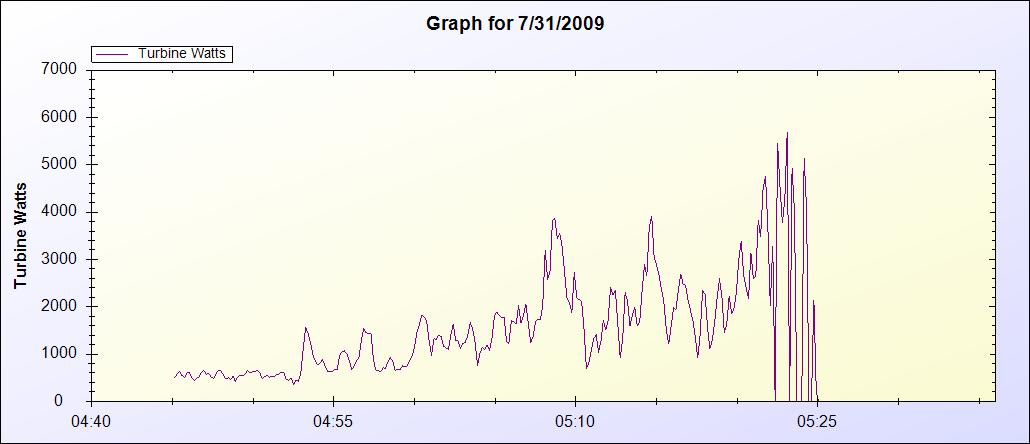

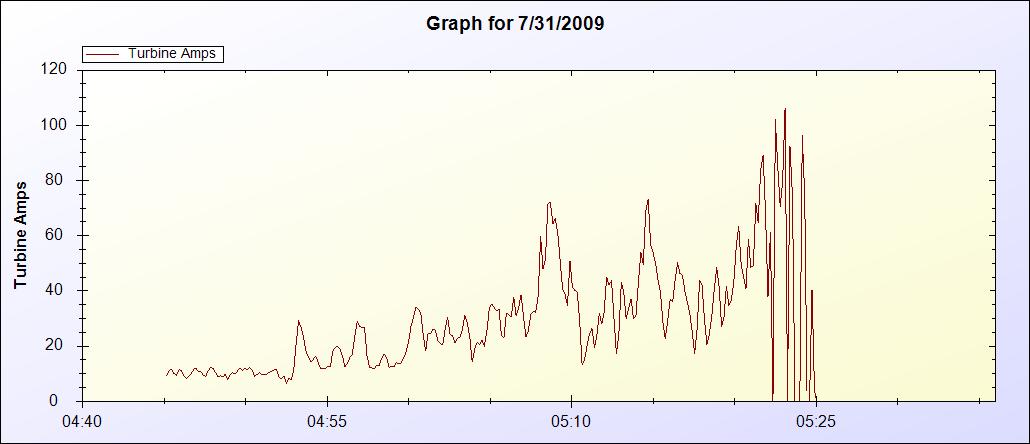

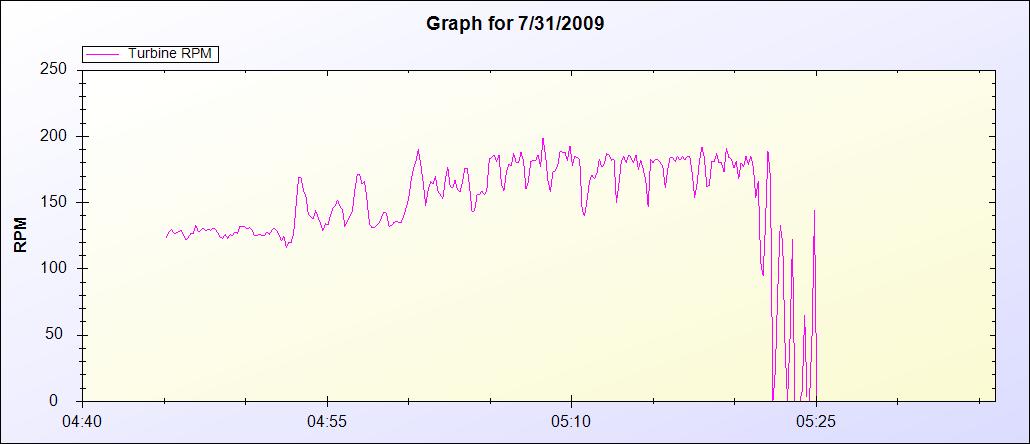

The graphs showing watts/amps output and turbine rpm confirmed it as shown below:

Output was peaking out at at around 100amps, 6000 watts, while at below 200 rpm!

The graphs also tell me that the furling still is not working properly, in spite of lightening the tail vane by 20lbs, so I will be finally adding about 2-1/2" more offset from the yaw bearing.

Initially I was hoping that it was the plug/receptacle, but upon further inspection it appears to be the stator. Using some binoculars I do not see any tell-tale discoloration of the stator, the turbine still rotates in a stiff wind but it does so very slowly.

So it looks like a stator replacement is due. The last stator I used 14 gauge wire, two-in-hand, with 59 turns per coil.

I am not sure but I will see if I can fit coils wound with 15 gauge, three-in-hand, if so will be shooting for about 52 turns per coil. Worst case is that I use same coil configuration as last time. This time, no matter which direction I go with the coils, I will be excessively insulating the coils and phase wires from each other to (hopefully) prevent this from happening again.

I know that others in the past have said that the wires in the stator vibrate (causing humming) and I have to wonder that if adjacent coils are actually touching if the vibration could cause a short to develop?

This whole situation is compounded by the fact that the day after I got the 17'er flying again I broke my calcaneous (heel bone) into 3 pieces, and am in a cast for at least 8 weeks...

But during the interm I am accumulating the wire and parts needed to fabricate the stator.

Still learning,

Dan Lenox