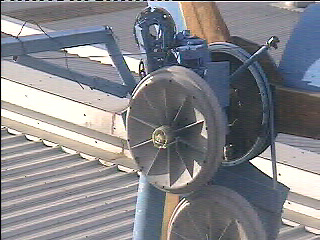

Still got to paint the blades, make bigger hub extensions , a guard over the belt and adjust the clutch cut in pot, my most advanced mill named after bobn R.I.P.

It has a 100 s delta (lo cut in low amps 14amps at 12 v for lo wind around 60% efficient) on a direct drive shaft which uses flat belt on a grooved magnetic ring it has a 2 to 1 ratio to a car air conditioning clutch on the front of the other f/p 80p series (hi cut in 42 + amps around 90 % efficient minus belt loss for hi wind) , with spring tension on pivot. On a 3 inch pole with a smaller square tube inside and bolt through it to support the sealed Bearing (like a car tire on a roundabout) riding on a 3 inch pole /yaw.

It has 2 , 3phase rectifiers and a single 1 phase rectifier to power the clutch from the direct drive alt. it simply goes through a pot to a capacitor ( to stop the bounce )and then to a super low current relay, To switch the 2 amps to the clutch and engage the second alternator, In hi wind.

It has been tested by hand spinning and so far once erected no wind (first rule applies).

The prop is made out of heavier pallet timber for the blades they are thicker than they looks at the hub, glued and screwed to the plywood hub at front.

It has furling and electric brake (short all phases on direct drive alt so far), need to include bottom alternator and clutch override on the timer . Any ideas at all ? A timer /simple so it does not leave 2 amps going to bottom alternator but is used to stop and then turn off..

The change over or brake circuit needs to be a relay / capacitor type device . (read cheap here)

A small bit of advise to those of you that are thinking of using an F/P motor. It is important to tie the lock down nut to the rear of the rotor as it has a chance of unwinding under certain circumstances.