These are how the magnets are supposed to go. I'm not too sure how well they will work overall. The magnetic strength is very strong. I get 2,000 pounds of magnetic strength (very dangerous) in a small package. The biggest problem I have is that my coils can not be very big and I do not want to much bleed-over between two magnets. I also got too this of wire (18g and I think 15 or 16 would have been better). Because of this I am trying smaller coils and more of them in a 5 phase set-up. I have not put my generator back together (messed up the first stator). I also need to make better blades.

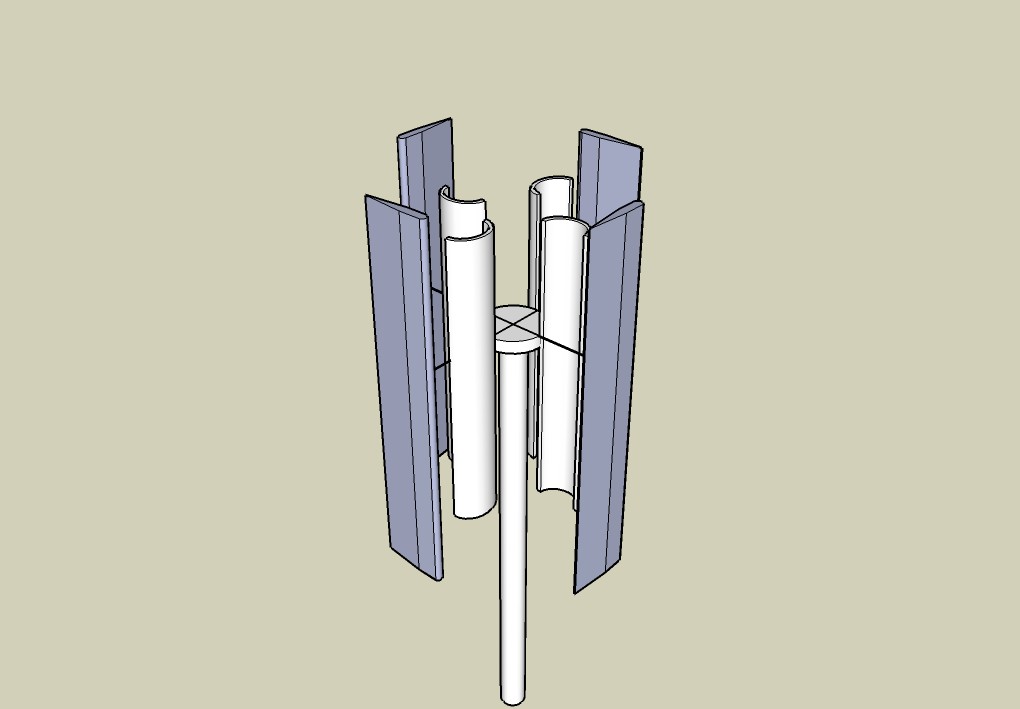

I am hoping on somewhere between 500 and 1000w. I think I need to use thicker wire, keep the coils narrow, but make them much thicker. The strength of the magnets are so strong, so I think the thicker stator plate will work well. I am going with a VAWT and some lift style aluminum blades. I will make it a hybrid likely with smaller push (or drag) style blades that will help with low wind start-ups (one very big drawback of the faster lift style blades).

This is a rough drawing of my idea...

Hopefully it will work and I can get a grid tie inverter to go with it. I am looking at doing a roof mount if the vibrations and noise is not too bad and the turbulence is not too bad without going with a taller tower. If I need a better tower then I will have to move this my sister or brother's house. I do not have any property for a full tower.