Active Load DC heater control for common 9/12 with logical-hysteresis using picAxe08M.

------------------------------------------------------------------------------------

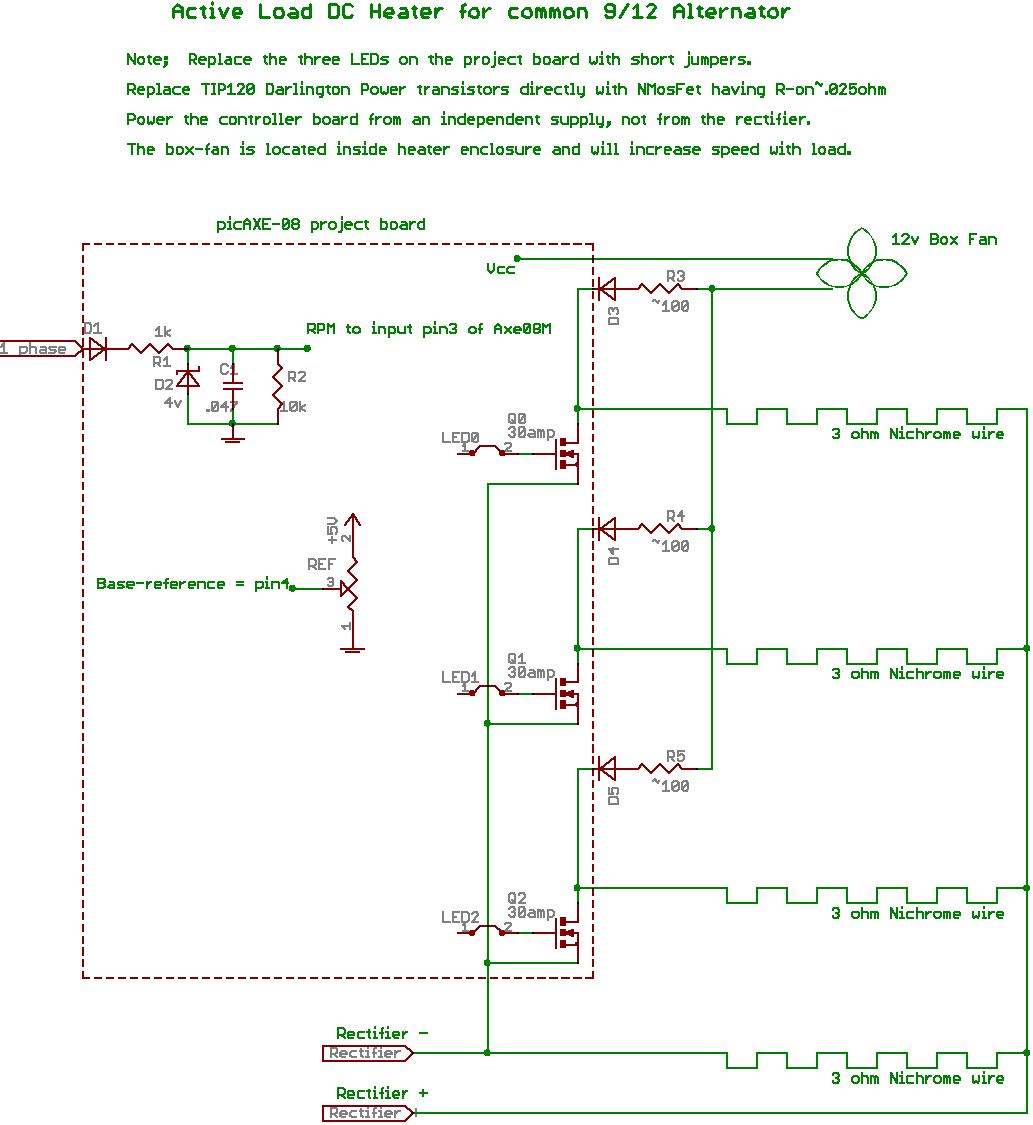

This controller was designed with, and put into production on, my PicAXE-ProjectBoard previously posted. The project board accommodates the direct replacement of the three output transistors with N-Mosfets (T220 case) required to switch multiple elements/loads at higher power levels with minimum losses. Also, to facilitate Blade-RPM reduction when load is increased, a hysteresis of +/-50RPM is built into the controller-logic. (Refer to the Axe08M Project Board diagrams in my files for additional information.)

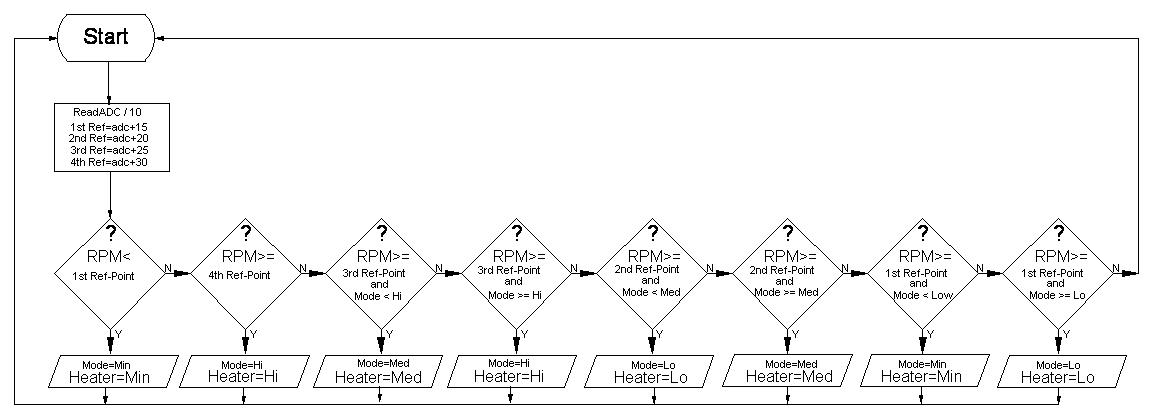

The controller continually monitors turbine RPM(pin3) and actively adjusts the load on the alternator at different speeds. Because every turbine has different power generating characteristics, a manual method of tuning/adjusting RPM to load is required. This was achieved with the high resolution analog to digital (10-bit ADC) input of AXE08M, which conveniently gives a 0-255 step reference to instruct the controller when to start applying the loads. On the controller, conversion of an analog input from a potentiometer, spanning the circuits supply rails, provides this adjustment which is used to set the load engagements points for efficient harvesting of turbine power.

This manual adjustment will result in an actively increasing "load" window starting with 150-300rpm (for larger machines) sequentially in 25 steps toward 400-550rpm for smaller machines. With proper adjustment, the controller will maintain `over-speed' control, and tames the turbine while tracking maximum power for heat generation. As always, a properly adjusted furling system is required, and necessary, for winds driving the turbine beyond this control-window. Transmission line loses should be considered.

The prototype includes four heater elements, each made from 3ohms of Nichrome wire salvaged from spent dryer elements. Note; different resistive loads, and combinations of, may result in more efficient harvesting of power, however, do not exceed "total-equivalent parallel resistance" less than that of the alternators single-phase resistance. This controller was not designed to run directly from the battery-bank, but as a diversion of power after batteries are charged or as a completely independent variable heat source.

You will fine the controllers AXE-code(basic) in my files, which is heavily commented and should be self explanatory, even for the novice programmer.

The following is a logical flow chart of the program for clarity. (You may have to print this image for legibility.)

Comments and questions are welcome.

Doc.

Moved to the proper section.