I purchased the 32 mags 3 x 1 1/2 x 3/4 from our host, and used a 18 in. 1/2 thick disc as Dan said the mags were a little too close together on his model. I used West Epoxy on the 2 rotor disc

My stator is wired for 24 volts and Dan did his for 48 volts. The stator is cast in fiberglas.

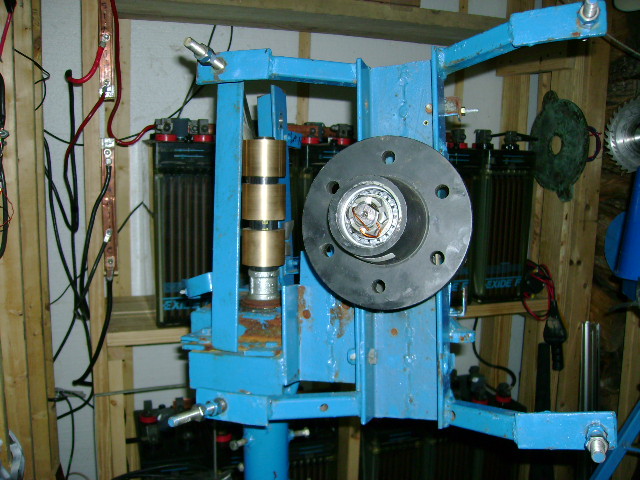

I took Dan,s advise and used a 6400 lb axle and spindle

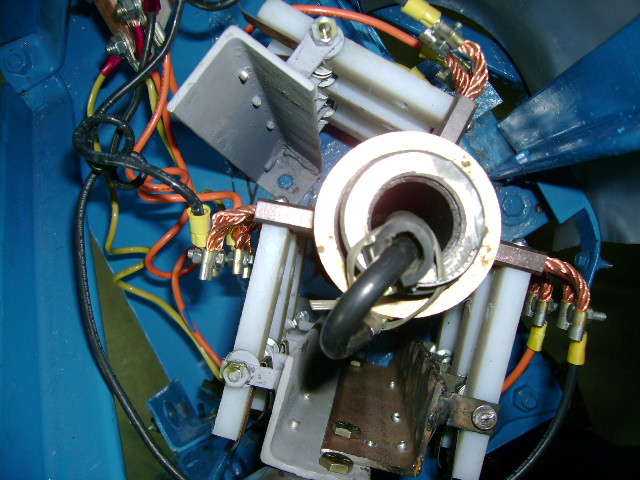

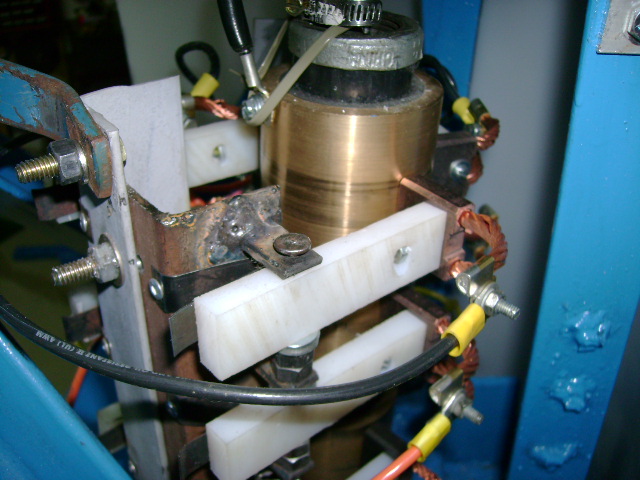

This is where I started to add a few of my own idea,s. I use 3 sliprings on this model and will take 3 cables of 2/0 160 feet to my 24 volt array. This is a top view of my slipring and brush assembly.

I am using 3 brushes on each slipring for a total of 9 brushes. This machine will be putting double the amperage as Dan,s because his was 48 v and mine is 24 v Somewhere I came across a discussion and was said Dan,s was puting out 83 amps. So at 160 amps divided by 9 brushes, would be 17 amps per brush. These are starter brushes and are rated for 600 amps. Should be an easy life even if my calculations are off.

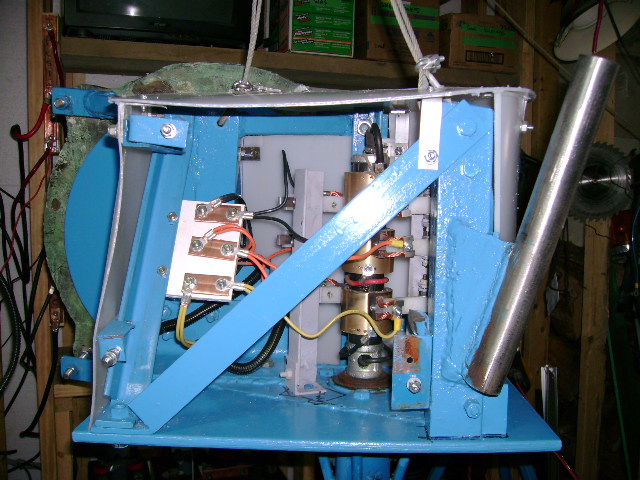

This is a rear view of my Dual Rotor with the rear panel off. This machine is covered as we get all kinds of weather in the Northeast. I used the buckets that the wire came in to cover the sliprings, brushes and my Yaw bearing. The buckets are slightly larger than 5 gallon cans

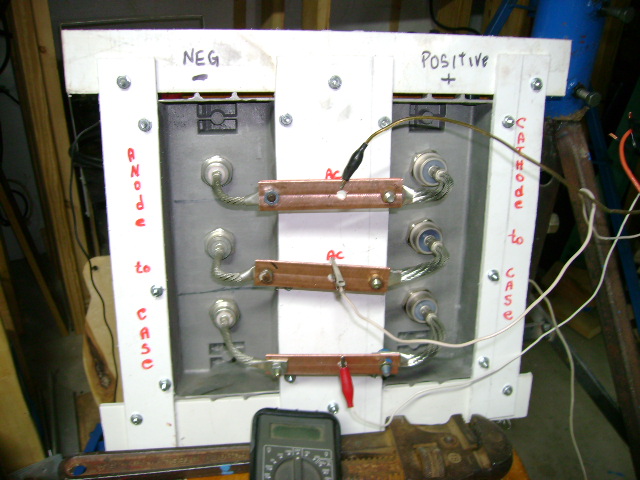

I am using 6 stud rectifiers in a homemade heatsink with fans and could be modified with larger heatsinks if they show any sign of overheating.

I have made a knife switch to control this machine and will probably rig up a load to short it into instead of the stator taking the heat.

Seen a post a week or two ago about a similar sized machine with a homemade braking system. So I,m giving it some thought.May add a brake too. Hey I had one of these get away in 72 mph gale and I nearly had a heart attack watching it. Used up a considerable amount of toilet tissue too. If it ever happened again, well I,m leaving home and let the wife look after it.

I want thank you guys for the help you all give me, last 2 years Flux,Dan B, Shadow, Wilbur, Dave and everyone else. I would not be raising this 17 ft.Dual Rotor machine if it were not for you. Mitcamp