I thought I'd try my hand at the famos Zub-Woofer pipe blades.

My problem was trying to cut a straigt line down the lingth of the pipe.

So I built a box of scrap wood that fits tighly around the pipe. Then I deturmind the center of the box and cut the box and the pipe together.

Heres the box and the 6" pipe befor the pipe went into the box.

Next the pipe is in the box.

Now the box is marked for cutting although I used the saws fence to set center.

Here I clamped the pipe to the box so it could not move and scew my straight line.

This shows how the saw blade will line up and miss the clamps.

After the cut I secured the cut opening with a scrap of plywood.

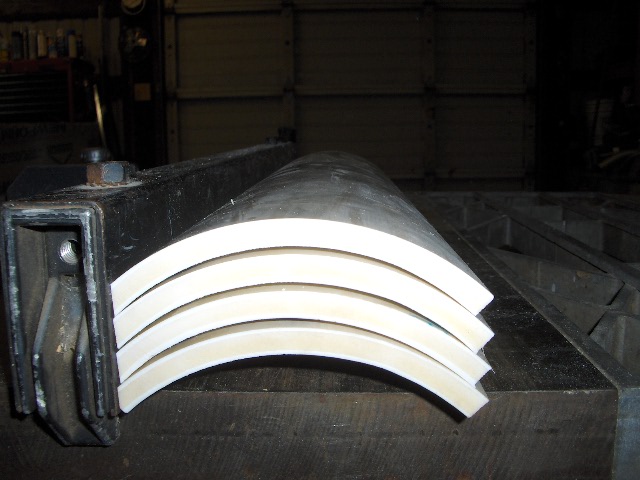

Here are the 4 slices of pipe after the ruff cut.

After the ruff cut I trued the blades to each other by 1 more pass on the table saw using the fence guid.

Here I'm seting the root to tip tapper angle.

Here is a smaller version I did last week. I did this one free hand. I want this next group to come out more even and matched.

I hope to build the triangle wooden hub this comming week? The root angle looks real good and the tip is allmost flat. Good cup and twist on the blade. I'm shooting for 48"s tip to tip.

JK TAS Jerry