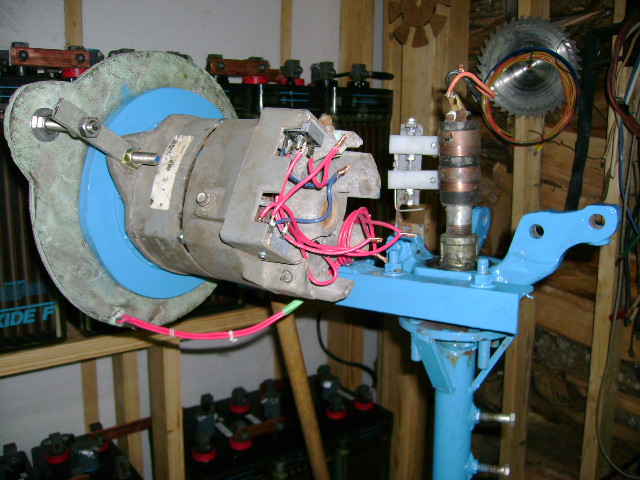

Since I had a pile of G.M alternators laying around, I decided to put them to use as a bearing for Hugh,s 4 footer. I removed the original G M stator and pressed the claw off of the rotor to save on the weight. I removed the rectifier assembly and installed 2 bridge rectifiers under the rear cover. It is easier to get to them if there was a problem.

I put the alternator back together with the 4 original bolts using spacers to make up the difference after removing the stator. This leaves a 1/2 inch gap. I used metal tape over the gap to keep the weather out.

I used a 9 in. disc 3/8 thick with a 7/8 hole in the center for the magnet rotor.I glued 8 magnets 2x1x1/2 down and then put the rotor in a mould. Using west bend epoxy I covered the mags, leaving a 4 in. island in the center. This rotor goes on the alternator first,with a spacer to keep it from rubbing the alt frame.

The stator was cast with hughs specs of 85 turns of #16 on a 3/8 former. The stator goes on next and is held in place by metal extensions attached to the original eye bolt lugs on the front of the alternator.

I used a second 9 in. disc on the front for 2 reasons, to complete the flux path for magnets and to attach the blades with short spreader bars. The spreader bars are just long enough to clear the bolts holding the stator.

I used a front wheel assembly from a dodge shadow to act as a yaw bearing. The axle hole allows the wires to go down the center of tower or pipe. In my case I use the hole to accomadate my slipring tower. The sliprings are insulated from the 1 in pipe with a teflon insert. You could just use the axle hole to run your wires down with or without sliprings.

You will need misc spacers on the alternator shaft to keep a air gap between the rotors and stator.

I have built a dozen of these 4 footers for cottages in the outback to charge batterys. Great for 5 to 20 amps depending on the wind. Hope this can shorten your build time. Mitcamp