In 2006, I wanted to increase my charging capability. When I compared the cost of

solar panels to the cost of wind generators for the same amount of power out,

wind power is looking good. Then bring in the fact that wind generators have

the ability to work 24 hours a day, while solar panels are limited to only several

hours each day, and there it is folks. We have a winner!!!

After a lot of reading on this site and several others, and 2 of Hugh Piggott's books,

I jumped in.

After looking at my stash of metal, I decided to go with Hugh's design for a 10 foot

diameter swept area. I didn't have the same bits that he called for in his plans, but I found

I had some heavy inch and a half angle that would substitute perfectly for his 3 inch

channel.

The next step was getting the rotors together. I used a half inch bandsaw blade (with the teeth

ground off) to make the surround to retain the magnets. Heated so it slips over the rotor

plate and allowed to cool and shrink to a tight fit. The magnets are potted in fiberglass

resin with talcum as a filler. You can see that the magnets stand proud of the resin, hopefully

to stir some air to help with cooling.

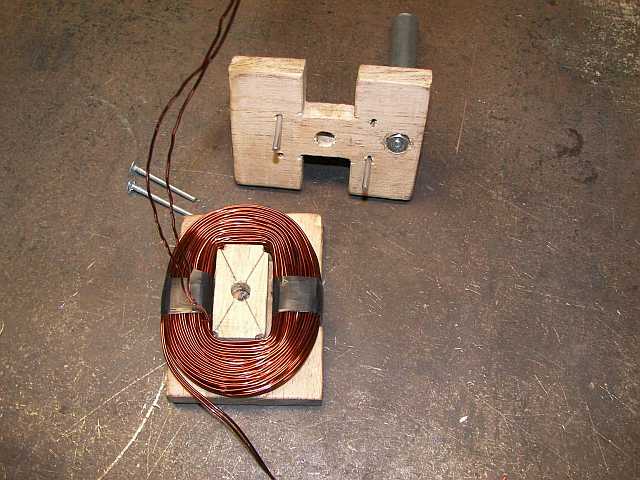

Then it was time to practice my counting. And after winding 9 coils, 17 Awg, 2 in hand,

75 turns, I was tired of counting.

This shot shows the stator freshly poured before the lid gets clamped on.

After curing for 24 hours, the stator came out of the mold very nicely.

This is the test fit for clearance before painting the stator.

Here, we're using the jacking screws to carefully assemble the generator head.

After all the metal and magnet work is finished, comes the part that most people seem

to be afraid of-----carving the blades. For me it is a quiet time. Lots of time to think, while

getting a good workout on the arms and shoulders. Here's the link to a previous posting

on carving blades.

http://www.fieldlines.com/story/2008/8/21/234112/976

For those who have never carved a set of 10 foot blades, the size is amazing when you

get them mounted. This shows a couple of my neighbors taking it down off the test stand.

They are both about 6 feet tall.

When the wind starts winding it up on the test stand, it reminds you

real quick to Be Careful. Those whirling blades can cause serious damage

to anyone that gets struck by one.

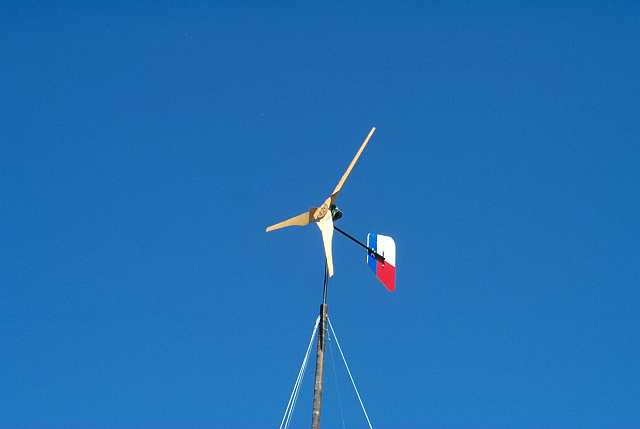

Here, it's being raised, in all it's glory. For those that know that I live in central Colorado,

you're probably wondering about the Texas flag on the tail. My girlfriend is from Texas,

and the flag seems to upset some city folks that have a cabin about 4 miles away. It's OK

for them to fly a German flag, (her mother is from Germany) but it upsets them that we don't

fly a Colorado flag. Some people's children!!!!!

This was completed and flying at the end of August 2006.

Ralph