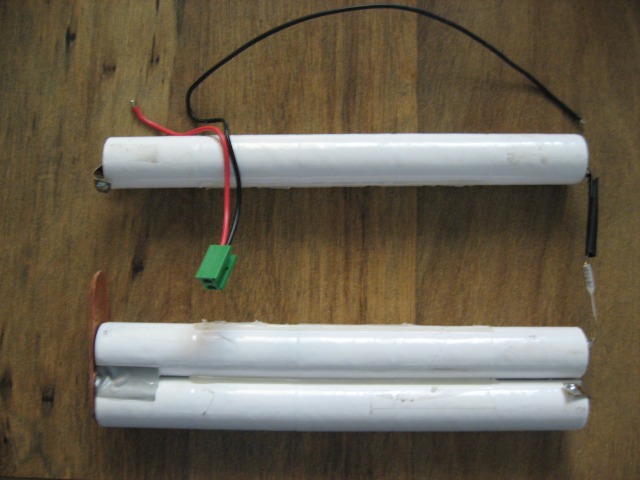

I received some NiCd battery packs from Bruce S.

According to Bruce, the packs are replaced after 2 years in service. They are tested, I assume, for voltage and amp hour rating. The packs are 18vdc @ 1.3 ah. All the packs are the same physical size and have a strip stuck to them showing the tested ah rating. The packs I received ranged from 105% down to 96%.

I decided to build a battery pack from these for use in one of my Currie Efolder bikes.

These are the packs as I received them. I believe Bruce has had other configurations of packs.

Here's the pack with the shrink wrap removed with careful use of a knife. There are 3 'strings', each string is made up of 5, 1.2vdc NiCd cells shrink wrapped in white. After many measurements and figuring, I decided the easiest way to get a pack made would be to cut one string off the original pack leaving me with a 12vdc , 1.3 ah string. Each string is hot glued(WOOHOOO... industrial hot glue!!!) together and it's a pretty simple procedure to slice through the hot glue and separate the strings. I used 4 of the packs which ranged from 105% down to 102%. In the top right hand corner of the pack between the first and second string of cells you can just make out a thermal cutoff that shuts the pack down if it gets too hot, I left these in place and ended up with 2 in each pack. So far this hasn't caused any problem.

CAUTION!!! THESE CELLS HOLD A LOT OF ELECTRICITY THAT'S JUST ITCHING FOR A WAY TO ESCAPE THE PACK. The original wires coming out of the pack are 18 AWG(American Wire Guage). Don't let the small size of the wire fool you. Depending on the type of insulation, 18 AWG has a rating of up to 25 or more amps although these packs are probably designed to deliver around 2 to 4 amps under load. Accidentally shorting these cells at any point between cells or strings will produce a discharge of 10 to 15 times the cells amp hour rating... i.e. BIG BAD BANG! Once the outer shrink wrap has been removed, the strips of metal connecting the individual strings of cells become exposed and one should use GREAT CARE while working on individual stings and individual cells.

Here is a pack with one string separated from the others. With a little forethought the 5 cell strings can be cut at the correct place to allow enough bus strip left over to use in reconnecting the strings.

Here you can see where I soldered 3 sets of 2 strings giving me 12vdc @ 3.9 ah. Be careful when soldering the tabs, too much heat will ruin a cell. You want to use high heat for a short period of time. I used a Weller 100/140 watt soldering gun on the high setting and used both the original cells tabs and other tabs off of old electric tool battery packs. Not pretty but it gets the job done.

This shows the other end of the strings with their original factory connections. Note the ends of the 2 thermal cutoffs pointing towards the camera.

Here I connected the 12vdc strings together to end up with a 24vdc pack @ 3.9 ah. Note the jumper wire running left to right in the middle of the bunch connecting both 12vdc packs. All the strings were hot glued together and the 2 packs were fastened together with packing tape.

This is the original setup of the Currie pack. 2-12vdc SLA @ 10 ah. It has an internal steel frame with a zippered outside bag.

This is the new NiCd pack.

The original Currie pack weighs around 16lbs, the new NiCd pack is around 8lbs.

I did an endurance test of both packs.

A non-pedaling circular route of 1.95 miles was run till system shut down(about 13.5vdc) on the NiCd and until a consistent (and self imposed) reading of around 20vdc for the SLA. I can't imagine the SLA lasting long if I took it all the way down to 6.75vdc per battery.

The course included stop signs and light traffic with a fairly consistent grade of about 2.3%.

From observing the volt meter I mounted on the bike and listening to motor noise, I determined the bikes top speed under electric power to be around 12.5 mph. At or above that speed I didn't use any throttle and let the bike coast. I did rolling stops at all 3 stop signs for a total of 6 rolling stops per complete lap.

Each battery was fully charged then left to sit for around 15 minutes before starting the test. Wind was light and variable... under 5mph.

Both batteries 'died' within about 300 feet of each other on the uphill half of the course.

The results were about identical and interesting.

NiCd SLA

Starting Vdc 27.6 26.3

Ending Vdc, after 5 min. rest 22.6 24.3

Trip length, miles 4.95 4.82

Time, minutes 26 25

Average speed, mph 11.4 11.5

Max mph, coasting 20 20.1

Kwh to recharge .11 .1