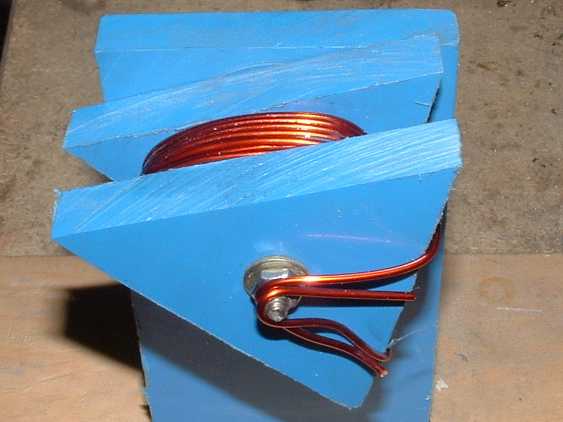

I made a new jig to hold the triangular coil. It is made from 1/2" polyethylene.

This first test coil has 35 windings of #14 guage copper.

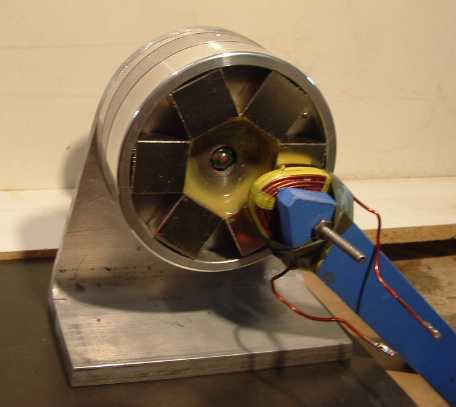

I mounted the test coil to my work bench and positioned the rotor in place.

The aluminium bracket is sitting on a rubber pad for this test.

Pictured here are holes drilled into the steel disk to high speed balance the rotor. Earlier today I balanced the rotor and added epoxy to secure the neos in place. At the speeds that this unit will operate at, there is no value in losing a magnet or two. I have not figured rim speed yet, but it is moving.

This frequency meter was reading 558 hz. So (558x60) = 33480 divided by three (the number of north poles) 11160 rpm.

This last picture is of a 60 watt 12 volt light bulb lit by one coil. The flywheel action only lasts a couple of seconds after I energize the unit to ~11000 rpm. Good enough for the test of this coil. I will now wind some different coils just for the fun of it.

Any comments welcome.

Joseph.