Above we see the frontal view showing the main components. Two 30 volt tape drive motors

[TDM] as a top and bottom generator-bearing combination. Rough sawn oak frame with plywood wing ribs and 4 mm corrugated plastic skin.

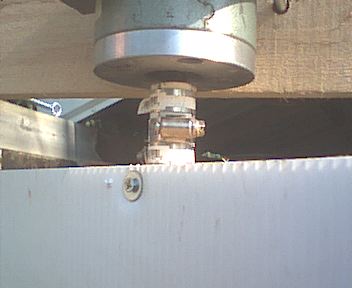

This is a closeup of the high tech TDM mounting setup.

Here you can see the 5/8th tdm shaft to 3/4" pvc coupling i made by sawing 2 cuts into the PVC and shoving the motor shaft into it with a shim of plastic flex tubing and clamping it with good old hose clamps.

I learned a lot while putting this together. For one thing the plastic does not conform well one way but does OK the other. One side is much smoother than the other. PVC is cheap and easy to work with but too flexible for a final unit.

It has an alignment issue with the 2 motor / bearings which I will look into today.

Its dimensions on the wing are 2 foot diameter by 2 foot tall. I know it needs multiple wings to self start and that is the plan eventually. Typical for me this is a mockup and test of the basic idea and to find building pitfalls before trying a full size 3 wing unit.

Cheers.

TomW