....Darrius! Finally after about 2weeks finally managed to curve some 'foamboard' and make a blade for a Darius type VAWT.

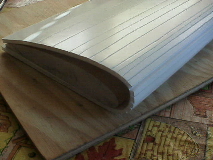

Using a very sharp utility blade I cut horizontal lines on the foamboard about 1/4 inch...cutting thru the top cardboard and the foam without touching the bottom layer of cardboard....after a few botched tries 2 or 3 ruined boards, 3 or 4 blade sharpenings, and 80 cuts later(there is about 20 horizontal partial cuts per blade.I finally managed the above...kinda resembles the top of a roll top desk. After covering the gaping cracks with white duct tape it turned out like this:

Then with a little bit of plywood I fastened it to a bicycle wheel like this...

I took it outside and of course the wind is only like about 3mph so I walked against the wind and it finally started spinning and a gust? of wind and it started spinning about 60-80rpm.but about that time I could see a car coming up Thomas Drive, so I hurriedly ducked back into the shop with my 'contraption' further testing was done in front a window fan at full blast. It goes fast enough to start shaking,(everything is a little out of balance) Think I'll modify it a little, like Pico Turbine. The blades are 30 inches high x 10 inches wide...I have them about 12 inches apart but it was suggested that they could be closer than this 6 inches maybe? Was wondering if the speed could be increased if the angle were changed or the angle could be automatically changed by the use of weights and/or springs to get the optimum speed...I really don't understand how this thing works but knock me over with a feather...It really works and much better than I had ever expected...(Thanks to all you people and especially Shane who got me started on this Darrius thing. Norm.