I had a lot of nutty customers that thought they

just had to run a lawnmower wide open to cut grass ....even more so when the blade became dull

even to the point of shortening the govenor spring! So...a lot of bent crankshafts.

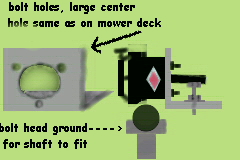

I decided to make a crankshaft straightener!

A friend of mine at the local salvage yard got a hunk of angle iron 12x12x16 and about 1/2 inch thick ....total price about 3 bucks! (I told you it was a long time ago )

I then took a 1x(8 inch??) bolt ground a nice rounded slot on the top of the bolt head for the crankshaft to fit.....bolted the engine on ...greased the washer and (fine threads)on the bolt...adjusted the bolt and turned the shaft so it hit the 'high' spot....then the fun began!

....turned that mini-screw jack about 4-5 turns with a 14" open end wrench then backed off about 1 turn or so turned the crankshaft 1 complete

turn and checked for run-out. Kept repeating this procedure until I could put a strip of paper between the bolt head and the shaft then turn the shaft so that it would barely touch the paper in one complete turn.

Good enough...always wondered how much runout even on a new engine???

I used to charge about $10 bucks to straighten a crankshaft, warning the customer that it might not hold up in severe service.

Needless to say the crankshaft straightener payed for itself many times over!

I finally quit doing it since I'm a little paranoid and was concerned about the safety involved with running an engine very fast in the first place.

More commnts and opinions on this to follow....

( :>) Norm.