Well here's the first

This one didn't balance well for I think a few different reasons but I never expected to nail it on the first try.

In reply to a few questions from the other post. For ed, it did do about 80 - 100 rpm in 5-7 mph winds and about 300 in 15-ish so that puts it in the tsr 7.5 range. After that it crashed.

nothing to lose, the white counter balances are indeed just stubby blades for three reasons, one - to provide additional lift and hopefully offset some of the one sided torque of the main blade, two - the 120 offset is to give the dynamic balance of a three blade, three - to reduce drag and turbulence by having the counterweights profiled rather than round or square etc.

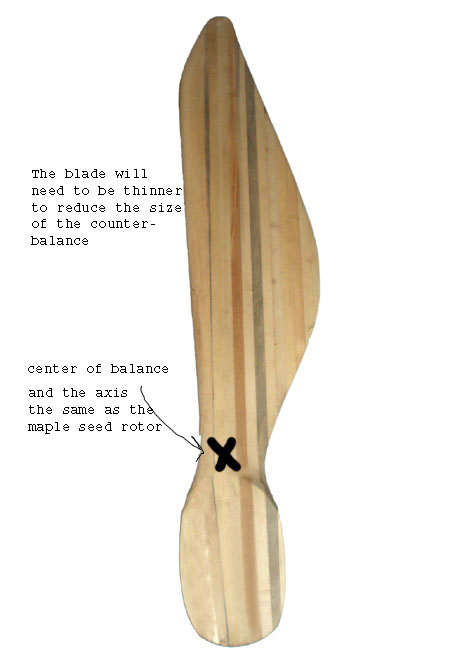

ted, I'm abandoning the 120 offset counterbalance for now because it has proven to be harder to do than I expected I'll revisit it after I learn how to balance this in a two blade format and I'll likely try to bring them in closer to the hub. see the next generation plan.

truman, I'm about 100% confident that at some point in the future I'll build a three blade rotor with blades like this thing has, It has alot of torque in low wind due to the blade area. It would offend anyone who is worried about high wind performance but not me and I think it would look really cool, lol.

For the next generation I'm going to mimic the maple seed even more and use the single counterweight just like it does till I learn more about this.

Here's a photoshop mutation of the above to give you an idea what it will look like and below is the original 2" norm turbine.

this is what started it all

me blowing on it during photo

Having fun if not success.

nuts